Thermal Imaging Applications in Parts Quenching Processing Monitoring

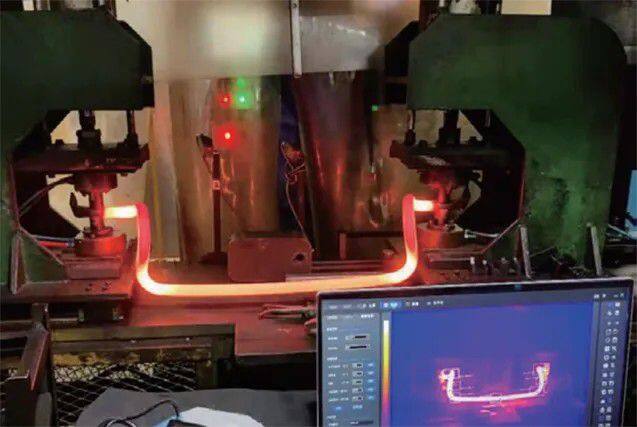

The hollow-pipe quenching machine uses high-frequency currents to heat up and cool down the surface of the workpiece. In this way, heat treatment is implemented for the surface-hardened layer, and the center’s temperatures and the workpiece’s bend are monitored. Whether the monitored temperatures satisfy certain standards is the basis for determining whether the workpiece is qualified. A certain difference exists between the temperatures at the center and the bend of a workpiece. The workpiece is regarded as qualified when specific values are reached. When a workpiece is heated by high-frequency currents, the workpiece will be scrapped with a loss generated if the highest processing temperature is reached.

The traditional point temperature measurement mode cannot identify the specific high-temperature point of the workpiece. For its center and bend, multiple devices need to be installed for temperature monitoring, which is inefficient and costly.

Thermal cameras are used for real-time collection and display of temperature data on each part of the workpiece. In this way, staff can identify the highest temperature point of the workpiece and generate a temperature change curve. Also, staff can configure high-temperature thresholds; if the temperature in the workpiece reaches the set threshold, an alarm signal will be generated, which will control the external quenching machine to stop heating and prevent the workpiece from being damaged by overheating.

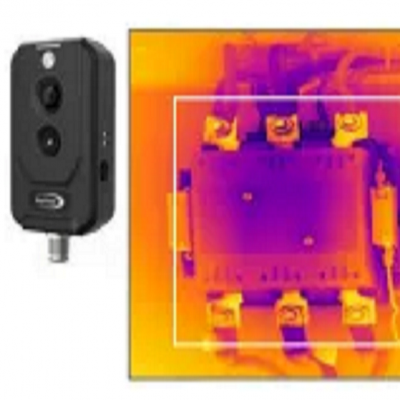

· Small and easy to install and use. It is suitable for the use environment and can link the hollow-pipe quenching machine.

· Non-contact temperature measurement does not affect the objects to be measured, without requiring a pause of the device to remove the workpiece for temperature data collection.

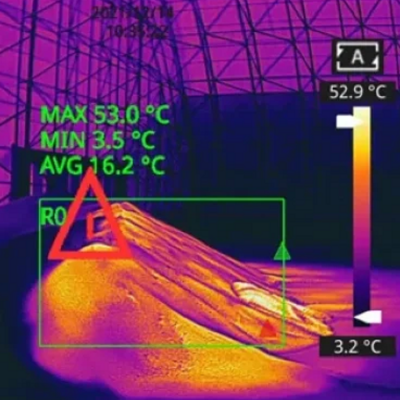

· Real-time reading of detected temperature data can automatically display the highest temperature point and temperature data in the area, visualizing the problem and locating it accurately.

· Multiple temperature-measured areas, such as points, lines, and surfaces, can be configured according to actual requirements, with no need for temperature measurement through a single point.

· The device has a wide temperature measurement range from 0°C to 1500°C, which meets the ultra-high temperature measurement requirements, and strictly controls the heating temperature of the workpiece.

· It can automatically generate temperature change curve records, capture images of the onsite situation, and view the heating temperature in real time.

· The device supports high-temperature point alarms. You can set multi-level alarm thresholds. If the temperature reaches a threshold, the alarm signals are provided to control the external quenching machine.

Main Applications of Thermal Cameras in Parts Quenching Processing Monitoring· The hollow-pipe quenching machine uses high-frequency currents to heat the surface of the workpiece, and the temperature in the heat treatment needs to be measured. Read the measured temperature data in real time, and directly monitor the heating and warming detection processes.

· Multiple temperature measurement points need to be set to monitor the temperature changes of each area so that the temperature values can be compared for each area, especially the highest temperature point at the center and bend of the workpiece.

· High-temperature alarms need to be configured in the measured area. Alarm signals need to be provided to stop the heat treatment of the hollow-pipe quenching machine if the temperature of any point in the area reaches the specified upper threshold.

It is recommended to use it with Raythink’s professional industrial temperature measurement analysis software:

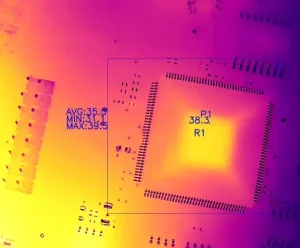

1. For different-shaped workpieces, modifications to the size, quantity, position, and shape of the temperature-measured area are supported, with no need for a single device and workpiece adaptation.

2. The temperature changes in the measured area can be recorded. Based on the change curve, it identifies the temperature value at a certain moment and the highest temperature throughout the heating process, and compares the temperature difference between the center and the bend of the workpiece.

3. The image data and temperature data can be stored on the back end for secondary

analysis later, making the application more flexible and reducing the cost.

4. The temperature threshold for an area is configurable. When the temperature in the measured area reaches the set threshold, an alarm is automatically raised. The device outputs a level alarm signal and a command signal to control the external quenching machine to stop heating.

Recently Posted

-

Passive vs. Active Thermography: How Thermal Cameras Enable Different Inspection Techniques

February 5, 2026In power grid inspections, industrial equipment maintenance, and security monitoring scenarios, thermal cameras have bec Read More

Read More -

TN220 Thermographic Cube Camera: Cigarette Pack-Sized Infrared Device Unlocks New Safety Monitoring

February 4, 2026In the field of industrial safety monitoring, three core pain points have long plagued operation and maintenance teams: difficulty Read More

Read More -

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More