Handheld Thermal Camera Keeps an Eye on Gas Stations to Guard Against Gas Leak

Gasoline is a highly volatile organic compound (VOCs). If the vapor at gas stations is not recycled sufficiently, it will cause environmental pollution, endanger health, cause oil loss, and even cause safety accidents. The introduction of the Raythink handheld infrared gas thermal camera provides powerful support for vapor recovery at gas stations.

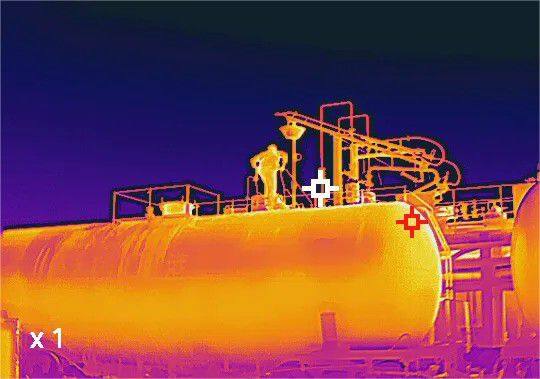

Main Application of Handheld Thermal Camera at Gas Stations1. Leak Detection for Breather Valve of Tank TrucksAfter analysis, the causes of leakage of the breather valve of the tank truck include rust, scratches on the contact surface between the valve and the valve disc by hard objects, deformation of the valve disc or valve seat, and inclination of the valve disc guide rod. Currently, mechanical inspection is commonly used to detect breather valve leakage, mainly involving manual climbing to check the flexibility of the mechanical movements above the tankers. However, this method can hardly intuitively discover potential problems, with great limitations.

To solve this problem, Raythink handheld infrared gas thermal camera RG600 is introduced, which can directly observe the gas leakage under the vehicle, thereby significantly improving the inspection efficiency and detection effect. By using this non-contact, remote measuring detection tool, breather valve leakages can be identified more intuitively and conveniently, providing strong protection for the safe operation of tank trucks.

(Raythink handheld infrared gas thermal camera RG600 can directly discover gas leakage under the vehicle)

2. Gas Leakage Detection of Oil Unloading Interface and Refueling Pipe JointIn actual use, the oil unloading interface and the refueling pipe joint are prone to oil and gas leakage because of such factors as insufficient flange tightness, aging and fall-off of the rubber pad on the back of the manual metering port, and corrosion of the valve. Gas leakage will increase the risk of explosion, affect product quality, and increase operational risks.

The use of the advanced Raythink handheld infrared gas thermal camera RG600 can visually and intuitively detect and locate potential gas leakage positions, but also it can help operators to quickly determine whether there is a leakage point, to which measures are taken timely for repair. It can effectively prevent the risks brought by vapor leakage, and ensure the safety and stability of the production environment.

(Raythink handheld infrared gas thermal camera RG600 helps operators quickly determine whether there is a leak)

3. Air Leakage from Vacuum Pumps such as Oil Pumps and Vapor Recovery PumpsDuring the operation of the vacuum pump, if it is poorly sealed, it is very likely to cause gas leakage. Once vapor spreads inside the oil pump, it will bring about potential environmental audit risks. The infrared gas thermal camera launched by Raythink can accurately locate and identify the leak positions, thus effectively dealing with leaks.

Raythink Technology relies on its technological advantages and industrial cluster advantages to solve the pain points of gas detection for energy and chemical users. In the future, Raythink Technology will continue to insist on the innovation of infrared thermal imaging gas detection technology and contribute more products and solutions to the industry.

Recommended Products

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More