Explosion Proof Security Cameras

1. What Is an Explosion-Proof Security Camera?

An explosion-proof security camera is surveillance equipment designed to operate safely in hazardous environments. It achieves this through specialized structural design (such as flameproof enclosures and sealed encapsulation) and material selection. These features prevent electrical sparks and high temperatures generated by internal circuits and components from propagating outward. Simultaneously, the camera resists the ingress of flammable or explosive gases and dust from the external environment. Its core characteristic is obtaining authoritative explosion-proof certification, confirming compliance with safety standards for specific hazardous environments. Every stage—from design and manufacturing to testing—adheres to stringent explosion-proof specifications.

1) Core Advantages of Explosion-Proof Security Cameras

· Safety Without Hidden Hazards: The core advantage lies in “explosion-proof” design. Through flameproof and intrinsically safe construction, it eliminates explosion risks caused by electrical sparks or high temperatures, meeting fundamental safety requirements in high-risk environments.

· High Environmental Adaptability: Features resistance to high temperatures, low temperatures (-40°C to 60°C), dust, and water (IP68 protection rating), enabling operation in harsh conditions such as humidity, dust, and extreme temperature fluctuations.

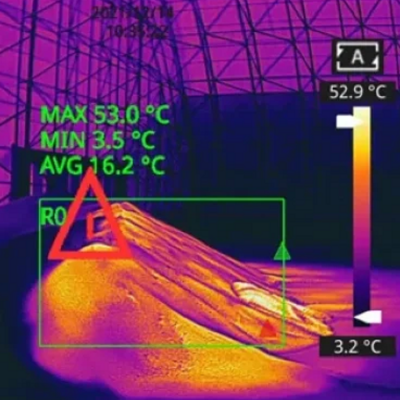

· Precise and Comprehensive Imaging: Mainstream models incorporate dual-spectrum imaging technology (thermal imaging + visible light), enabling clear target identification in low-visibility conditions like darkness, fog, or haze. Select models support temperature measurement (-20°C to 550°C), enabling temperature anomaly alerts.

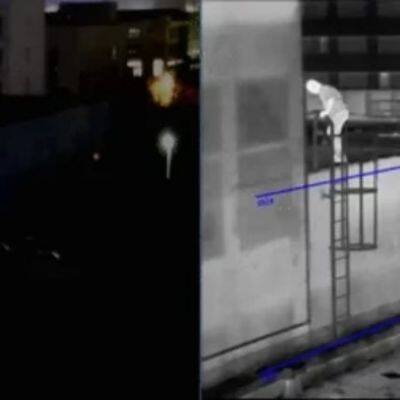

· Rich Intelligent Features: Integrated with intelligent detection capabilities like perimeter intrusion, tripwire intrusion, and fire detection. Supports alarm linkage (recording, snapshot capture, email notifications) to reduce manual monitoring costs.

· Stable and Reliable: Constructed with 304/316L stainless steel housing for corrosion and impact resistance. Select models support local SD card storage (up to 256GB), ensuring continuous recording during network outages and maintaining uninterrupted surveillance operations.

2) Why Must Hazardous Environments Employ Explosion-Proof Designs?

Hazardous environments (such as chemical plants, mines, and flammable storage facilities) contain combustible gases (e.g., methane, hydrogen), vapors, or combustible dust. The electrical circuits and mechanical friction of conventional cameras can generate sparks or high temperatures. If these come into contact with flammable substances, they can easily trigger explosions or fires.

The core value of explosion-proof design lies in “risk isolation”: it uses flameproof enclosures to isolate internal ignition sources from the hazardous external environment. Simultaneously, the enclosure possesses sufficient mechanical strength to withstand pressure and prevent rupture even if an internal explosion occurs, thereby preventing flame leakage. Furthermore, explosion-proof equipment must undergo rigorous temperature class certification (e.g., T6 class, maximum surface temperature ≤85°C) to ensure operating surface temperatures remain below the ignition temperature of combustible media, eliminating safety hazards at their source.

2. Raythink Explosion-Proof Security Camera Recommendations

1) TE365 Dual-Spectrum Explosion-Proof Bullet Camera

Core Certifications:

Explosion-proof rating Ex db IIC T6 Gb, Ex tb ⅢC T80℃ Db, suitable for Class IIC gas explosion environments (highest hazard level) . The T6 temperature class ensures the device surface temperature does not exceed 85℃, making it suitable for most high-risk scenarios.

Technical Highlights:

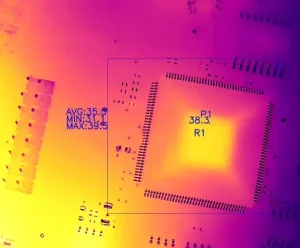

· Dual-Spectrum Fusion: 12μm thermal imaging (640×512 resolution) + 5MP visible light (2560×1920 resolution). Supports picture-in-picture and dual-spectrum fusion modes for clear target identification day or night.

· Precision Temperature Measurement: Measurement range -20°C to 550°C, accuracy ±2°C or ±2% (whichever is greater). Supports global, point, line, and area temperature measurement with linked alarms, meeting equipment temperature monitoring and fire warning requirements.

· Intelligent Protection: IP68 rating, 304 or 316L stainless steel housing, withstands extreme temperatures (-40°C to 70°C) and humidity environments (<95% RH), corrosion-resistant and dustproof.

· Stable Operation: Supports local storage via Micro SD card (up to 256GB), and 1 RJ45 Ethernet port.

2) TE464T1 Dual-Spectrum Explosion-Proof PTZ Camera

Core Certification:

Explosion-proof rating Ex d IIC T6 Gb/Ex tD A21 IP68 T80℃, meeting gas explosion protection requirements. IP68 protection combined with corrosion-resistant materials ensures suitability for demanding outdoor high-risk environments.

Technical Highlights:

· Pan-Tilt Panoramic Surveillance: Continuous 360° horizontal rotation with -90° to 90° vertical adjustment. Both horizontal and vertical speeds reach 0.1° to 40°/s. Supports multiple scanning modes including preset points, patrol groups, and linear scanning to cover extensive monitoring areas.

· Dual-Spectrum Imaging: Thermal imaging (640×512 resolution) + 4MP visible light (2688×1520 resolution). Visible light lens focal length ranges from 6.5mm to 130mm.

· Intelligent Linkage: Supports intelligent event analysis including tripwire intrusion, zone intrusion, and fire detection. Triggers video recording, snapshot capture, and email alerts. Features 1 RS485 interface for controlling external alarm devices.

· Extreme Environment Adaptation: Operating temperature range -40°C to 60°C, humidity <90% RH, power consumption ≤100W (when temperature control system activates), weight 27kg. Heavy-duty structural design ensures resistance to wind loads and vibrations.

3. Typical Application Scenarios for Explosion-Proof Security Cameras

1) Chemical Industry

Chemical parks, petrochemical plants, and fine chemical facilities contain hazardous sources such as flammable and explosive gases (methane, ethane, hydrogen), corrosive gases, and high-temperature reactors. Raythink explosion-proof cameras, rated Exd IIC T6 Gb, withstand the highest-level gas explosion risks. Dual-spectrum imaging technology penetrates smoke and steam to monitor reactor temperatures and pipeline leaks in real time. Intelligent fire point detection identifies early fire signs, triggering alarm outputs to secure critical response time.

2) Manufacturing Facility Monitoring

Production facilities in automotive manufacturing, metallurgy, and machining involve risks such as high-temperature equipment, welding sparks, and metal dust. Conventional cameras are prone to damage from heat and dust or may trigger safety incidents. Raythink products feature an IP68 protection rating that effectively blocks dust ingress, with an operating temperature range of -40°C to 60°C to accommodate fluctuations in factory environments. Temperature monitoring capabilities track equipment operating temperatures to prevent failures caused by overheating. Intelligent detection functions identify unauthorized entry and lingering in hazardous zones, ensuring production safety.

3) Mining Scenarios

Mining environments such as coal mines and metal mines pose risks of methane gas and coal dust explosions, while coal piles are prone to smoldering hazards. This demands extremely high standards for explosion-proof capabilities and environmental adaptability in safety monitoring equipment. Raythink explosion-proof cameras, certified with Ex tb IIC T80℃ D explosion protection, precisely meet the requirements of such high-risk environments. Thermal imaging technology operates independently of ambient light, enabling clear identification of personnel locations and equipment distribution within operational zones. The Raythink TE464T1 Dual-Spectrum Explosion-Proof PTZ Camera‘s 360° rotation capability provides comprehensive surveillance coverage of mining areas, transport corridors, and coal stockpile storage zones. Its integrated temperature measurement module monitors coal pile temperature changes in real time, delivering early warnings for smoldering risks. The product’s low-temperature resistance and vibration-proof design confidently withstand environmental impacts in mining scenarios, ensuring stable operation of surveillance equipment.

4) Flammable Material Storage Facilities

Facilities such as oil depots, chemical warehouses, and fireworks storage depots house large quantities of flammable, explosive, and corrosive substances. Safety monitoring must achieve 24/7 coverage with no blind spots or hidden hazards. Raythink explosion-proof cameras feature flameproof and sealed enclosures that prevent external combustible gases or liquids from entering the device. Dual-spectrum imaging enables continuous day-and-night monitoring, eliminating blind spots caused by insufficient lighting. Intelligent alarm functions trigger strobe lights and sirens upon detecting anomalies—such as excessive temperatures or unauthorized entry—while automatically recording evidence for documentation.

Conclusion

In high-risk environments such as chemical plants, mining operations, and flammable material storage facilities, security extends beyond mere “monitoring” to form a critical “safety barrier.” As a specialized manufacturer in infrared thermal imaging and intelligent sensing, Raythink delivers secure, reliable, and intelligent security solutions for global high-risk industries. Centered around its TE365 and TE464T1 explosion-proof security cameras, Raythink leverages authoritative explosion-proof certifications, dual-spectrum imaging technology, and extreme environment adaptability.

Whether for precise monitoring in fixed locations or dynamic patrols across large areas, Raythink explosion-proof security cameras precisely match requirements, mitigating safety risks at their source to safeguard industrial operations and personnel. For customized explosion-proof security solutions tailored to specific scenarios, contact Raythink’s professional team. We provide end-to-end services—from product selection and installation to post-deployment maintenance.

FAQs

1) What is the core difference between explosion-proof security cameras and ordinary cameras?

The core difference lies in “explosion-proof capability”: Standard cameras lack explosion-proof design, and electrical sparks or high temperatures generated by circuit operation may ignite combustible media in hazardous environments. Explosion-proof cameras, however, feature designs such as flameproof enclosures and sealed encapsulation to isolate internal ignition sources. Additionally, they undergo authoritative explosion-proof certification, enabling safe operation in hazardous environments. Furthermore, explosion-proof cameras exhibit significantly superior environmental adaptability (resistance to extreme temperatures, dustproofing, and waterproofing) compared to standard cameras.

2) How to choose explosion-proof cameras suitable for your specific scenarios?

· Consider the hazardous environment type: For gas explosion environments, select Exd IIC rating;

· Consider temperature requirements: For high-temperature environments, prioritize T6 rating (lower surface temperature);

· Consider monitoring range: For fixed small areas, choose TE365; for large-area dynamic monitoring, select TE464T1 PTZ cameras;

· Consider functional requirements: For temperature measurement and hotspot detection, choose dual-spectrum models; for long-distance monitoring, select TE464T1.

3) What precautions should be taken when installing explosion-proof cameras?

· Installers must possess explosion-proof equipment installation certification and strictly follow the product manual;

· Installation locations should avoid direct impact and corrosion sources, ensuring the housing remains undamaged;

· Wiring must use explosion-proof sealed connectors to prevent air leakage at cable interfaces;

· Regularly inspect the integrity of the equipment housing and seals to ensure explosion-proof performance remains effective.

4) What are the advantages of dual-spectrum imaging (thermal imaging + visible light)?

Thermal imaging operates independently of ambient light, enabling target detection in darkness, fog, haze, and smoke while simultaneously providing temperature measurement. Visible light imaging delivers clear, detailed imagery for precise target recognition (e.g., facial features, license plates). Dual-spectrum fusion technology balances “all-weather surveillance” with “detailed identification,” overcoming the limitations of single-spectrum imaging. This makes it particularly well-suited for complex monitoring requirements in high-risk environments.

Recently Posted

-

Passive vs. Active Thermography: How Thermal Cameras Enable Different Inspection Techniques

February 5, 2026In power grid inspections, industrial equipment maintenance, and security monitoring scenarios, thermal cameras have bec Read More

Read More -

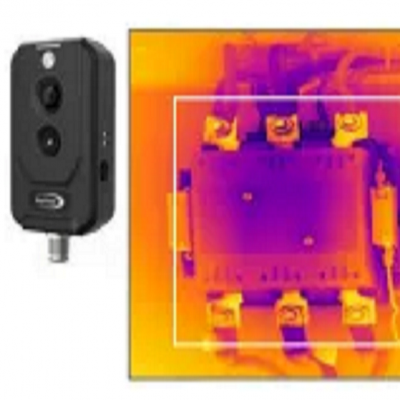

TN220 Thermographic Cube Camera: Cigarette Pack-Sized Infrared Device Unlocks New Safety Monitoring

February 4, 2026In the field of industrial safety monitoring, three core pain points have long plagued operation and maintenance teams: difficulty Read More

Read More -

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More