TN220 Thermographic Cube Camera: Cigarette Pack-Sized Infrared Device Unlocks New Safety Monitoring

In the field of industrial safety monitoring, three core pain points have long plagued operation and maintenance teams: difficulty deploying equipment in narrow spaces, hard-to-detect hidden hazards, and cumbersome operation of traditional devices. The Raythink TN220 Dual-Spectrum Online Temperature Measurement Cube Camera, with its compact cigarette pack-sized design, precise temperature measurement capabilities, and flexible adaptability, breaks through scenario limitations and becomes the preferred choice for safety monitoring in high-voltage power distribution, energy storage stations, lithium battery production, and other fields.

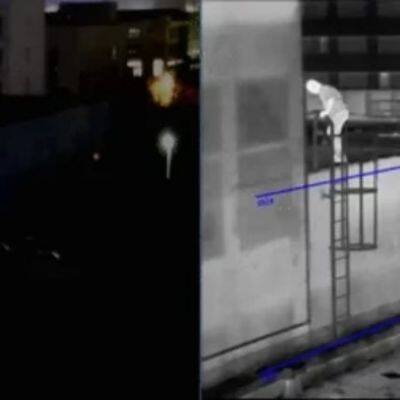

Traditional Contact Temperature Measurement | Infrared Thermal Imager Temperature Measurement |

| |

Advantages: · Cost-effective · Relatively high temperature measurement accuracy | Advantages: · Enables full-coverage measurement of target areas · Intuitively displays target temperature distribution · Simple operation without damaging the target structure · Supports video traceability · Simple wiring |

Disadvantages: · Complex wiring, easy to damage the target structure · Unclear target temperature distribution, prone to missed detections · Slow response with heat conduction delay · No video traceability | Disadvantages: · Relatively higher cost |

Device Introduction

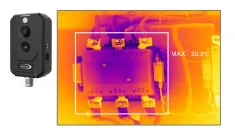

TN220 Thermographic Cube Camera

· Compact Structure: 93×56×31.5mm, sleek and portable like a cigarette pack, specially designed for narrow scenarios.

· Full-Range Temperature Measurement: Precise temperature measurement with rich details, featuring 256×192 infrared resolution and a wide field of view (90°×65.1° for infrared).

· Panoramic Imaging: Infrared thermal imaging + 2MP visible light view.

· Multi-Protocol Support: Compatible with ONVIF, Modbus, GB/28181, and IoT MQTT protocols, supporting independent IO alarm output.

· High Protection Level: IP67 rating for strong adaptability to harsh environments.

· Flexible Deployment: Supports POE power supply, enabling simultaneous power and data transmission via a single cable, reducing construction and commissioning costs.

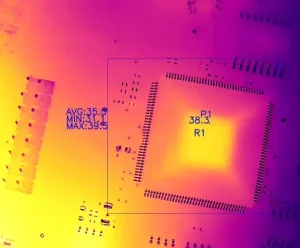

1. High-Voltage Switchgear

As a core equipment in power systems, high-voltage switchgear features dense internal components and complex electromagnetic environments. Poor contact or aging of cable joints and busbar contacts can easily cause local overheating. Manual inspections are not only inefficient but also carry significant risks of missed detections. Traditional contact temperature measurement requires deploying a large number of sensors, resulting in complex wiring and delayed response, which is difficult to meet real-time monitoring needs. With its compact 93×56×31.5mm size, the TN220 can be easily installed in the narrow space of switchgear without modifying the original equipment structure. Its IP67 protection level can withstand humid, dusty, and other harsh environments inside the cabinet. Equipped with POE power supply, it achieves power and data transmission through a single cable, greatly reducing construction and commissioning costs. The device is equipped with a 256×192 infrared resolution detector, covering a temperature measurement range of -20℃~650℃ with an accuracy of ±2℃ or ±2%. It supports multi-dimensional temperature measurement configurations (point, line, and area) and can accurately capture subtle temperature rises of 0.04℃.

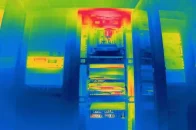

2. Energy Storage Stations

With the rapid development of electrochemical energy storage stations, the risk of thermal runaway caused by dense battery pack deployment has become increasingly prominent. Digital technologies are required to achieve safety status perception and early warning, and the TN220 is perfectly suited to this demand. The space inside energy storage containers is limited, and the TN220’s cigarette pack-sized design can be flexibly installed between battery packs. Its support for multiple protocols (ONVIF, Modbus, GB/28181, and IoT MQTT) allows seamless connection to the energy storage station monitoring system. The device can set multi-level alarm thresholds for key parts such as battery packs and cable joints. When slight heat accumulation occurs in battery cells, it can immediately trigger audible and visual alarms and link with refrigeration or fire-fighting systems, providing early warning hours earlier than traditional smoke detectors. In lithium battery energy storage scenarios, the TN220, through infrared thermal imaging + 2MP visible light dual-spectrum fusion technology, can not only visually present the battery temperature field distribution but also trace historical temperature data, providing data support for battery health status assessment and building a solid safety line for energy storage stations.

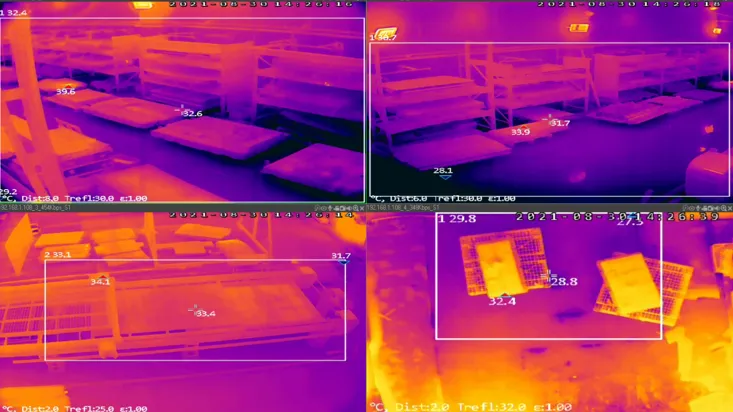

3. Lithium Battery Production and Hazardous Waste Treatment

During lithium battery production, processes such as formation, grading, and electrical performance testing involve charging and discharging operations, posing potential thermal runaway risks. Traditional contact temperature measurement can only achieve single-point monitoring and cannot capture the overall thermal field distribution on the battery surface. With a wide field of view of 90°×65°, the TN220 can cover a test station of 2.4m (horizontal) × 1.8m (vertical). Combined with automated guided vehicles (AGVs), it realizes 24/7 cruising monitoring, real-time recording of battery temperature data, and trend analysis. Once an abnormal temperature rise is detected, it immediately triggers an alarm, ensuring product yield and production safety. In hazardous waste treatment scenarios, lithium battery electrolyte is a flammable substance, and temperature monitoring of its storage area is crucial. The TN220’s 24/7 uninterrupted monitoring capability can real-time capture temperature changes of electrolyte storage equipment, avoiding fires or explosions caused by high temperatures. Meanwhile, the device supports independent IO alarm output, which can push early warning information to the monitoring platform in the first place, gaining valuable time for hidden danger disposal.

4. Core Technical Support of the TN220

The TN220’s multi-scenario adaptability stems from its solid technical core. The device adopts a self-developed 12μm uncooled infrared detector from Raythink, ensuring clear imaging and accurate temperature data. Its IP67 protection level enables it to adapt to various harsh environments such as high-voltage cabinets, energy storage containers, and hazardous waste warehouses. The POE power supply and single-cable transmission design simplify the deployment process and reduce installation costs. Equipped with professional temperature measurement and analysis software, it can realize multi-area alarm setting, historical data tracing, and linkage with third-party platforms, meeting the intelligent monitoring needs of different industries.

From high-voltage power distribution to energy storage safety, and from lithium battery production to hazardous waste management, the TN220, with its core advantages of compactness, flexibility, precision, and reliability, has become a “versatile player” in industrial safety monitoring.

If you are facing challenges such as deployment in narrow spaces or monitoring of hidden hazards, the TN220 may be a more cost-effective solution. Please contact us to learn more about Raythink products.

Recently Posted

-

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

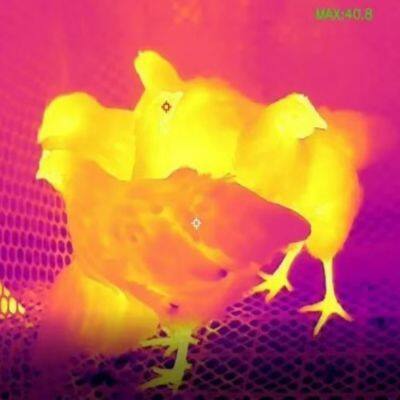

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More