Passive vs. Active Thermography: How Thermal Cameras Enable Different Inspection Techniques

In power grid inspections, industrial equipment maintenance, and security monitoring scenarios, thermal cameras have become essential tools for detecting hidden hazards and reducing operational risks. However, as the technology becomes more and more widely applied, concepts like “passive thermography” and “active thermography” appear with increasing frequency. This article introduces the working principle and application scope of these two approaches and clarifies the core distinctions between them, helping engineers and maintenance personnel understand and select the appropriate thermal imaging solution.

1. Basic Principles of Infrared Thermography

The essence of thermal imaging is “seeing” infrared radiation invisible to the human eye. Any object above absolute zero continuously emits infrared energy, which thermal cameras detect and convert into visual thermal images.

Fundamentally, a typical thermal imaging camera operates through these steps:

· Infrared detection: A lens collects infrared radiation from the object surface and focuses it onto a sensor array

· Signal conversion: The sensor converts radiation intensity into electrical signals, with different radiation levels corresponding to different temperatures

· Image generation: Through calibration and temperature calculation, the temperature distribution is mapped to a pseudocolor or grayscale thermal image

Based on this foundation, infrared thermography employs two usage approaches: passive thermography (without external stimulation) and active thermography (with applied external energy).

2. Passive Thermography: The Primary Solution in Industrial Applications

Passive Thermography detects heat by capturing the natural thermal radiation emitted by an object without applying external heat. The thermal camera analyzes the static or slowly changing temperature differences already present in the field, thus discovering anomalies. In industrial and security applications, passive thermography has become the primary solution.

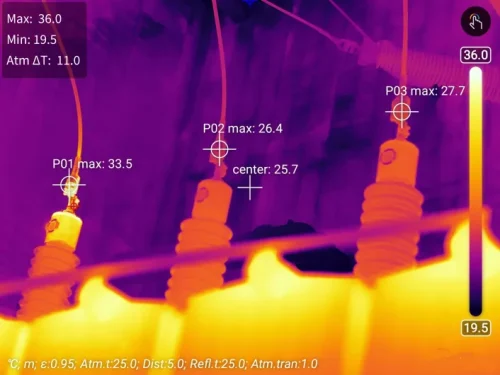

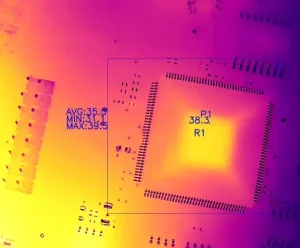

1) Power Industry Applications: Spotting Hidden Heat Sources

In power generation, transmission, and distribution systems, poor electrical contacts, undersized conductors, or local overloads can all cause noticeable temperature rises, which are often the earliest warning signs of failures and accidents. Passive thermography enables quick, non-contact inspection of numerous electrical nodes without powering down the equipment.

Typical passive thermography applications in power systems include:

· Substation and switchgear inspections: detecting abnormal heating in busbars, breakers, and disconnect switches for timely maintenance planning

· Overhead transmission line and connection checks: identifying abnormal temperature rises at clamps, terminals, and fasteners to reduce burn-out and trip risks

· Distribution panel and room monitoring: rapidly screening numerous circuits in low-voltage boards and distribution boxes, prioritizing those with thermal anomalies

Passive thermography integrates well with routine inspection. This integration allows trend analysis over time to distinguish between a temporary temperature rise and a persistent or worsening one.

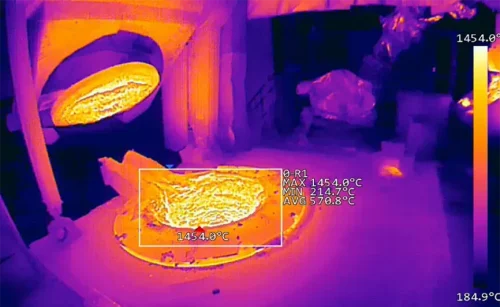

2) Metallurgy and Industrial Manufacturing: Inspecting During Production

In metallurgical and manufacturing environments, equipment naturally generates substantial heat during operation. Passive thermography enables condition assessment of the critical components without disrupting production.

Common passive thermography applications in industrial manufacturing include:

· Electric motor and bearing monitoring: detecting abnormal surface temperatures caused by overload, misalignment, or poor lubrication

· Transmission and Gearbox inspections: observing temperature patterns on housings to identify poor mesh engagement or lubrication degradation

· Furnace and high-temperature pipeline checks: evaluating insulation performance and identifying local structural damage through surface temperature distribution of metallurgical heating furnaces, heat treatment furnaces, and high-temperature piping systems

Using passive thermography, engineers can identify problems quickly by analyzing temperature patterns—immediate action is required when a component’s temperature is significantly higher than that of similar units or historical baselines.

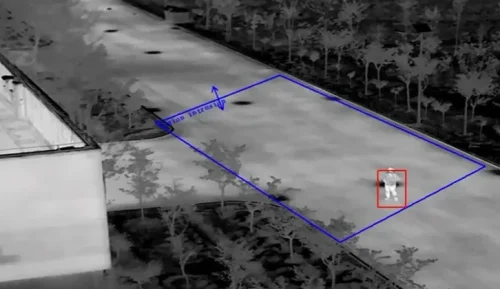

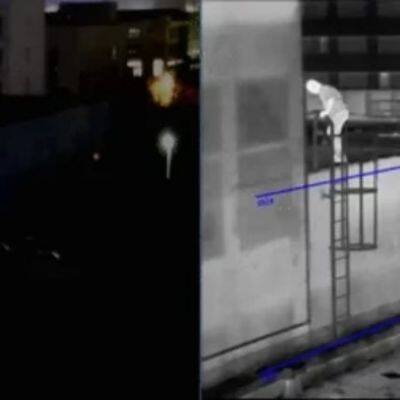

3) Security and Surveillance: Identifying Threats in Darkness

Thermal cameras provide distinct advantages in low-light and pitch-black environments because they do not depend on visible light but instead detect the target’s own thermal radiation.

Common passive thermography security applications include:

· Perimeter protection for critical facilities: detecting intruders during night hours or in poor weather, eliminating blind spots of visible-light cameras

· Port and airport surveillance: identifying thermal signatures from people, vessels, aircraft, and wildlife at long range to support identification and alarming

· Large outdoor facility security: nighttime patrols at chemical plants, tank farms, and storage facilities, where thermal imaging helps detect suspicious activity and potential fire sources

Passive thermography in security applications emphasizes not precise temperature measurement, but rather the ability to identify people, vehicles, and objects based on thermal contrast, along with resistance to environmental interference.

4) Fire Prevention and Early Alarm: Detecting “Hot Spots” Before Combustion

Many fires begin with undetected overheating. Passive thermography can reveal dangerous hot spots well before flames appear, providing a critical window for preventive intervention.

Typical passive thermography fire warning applications include:

· Warehouses and logistics centers: detecting abnormal heat sources in stacked goods, electrical infrastructure, or charging areas

· Waste dumps and coal stockpiles: continuous monitoring of surface temperature distribution to identify potential self-ignition points where spontaneous combustion risk exists

· Battery and charging facilities: monitoring electric device charging areas to spot overheating batteries or abnormal chargers early through thermal imaging

Passive thermal monitoring pairs effectively with alarm systems, triggering alerts when temperatures exceed set thresholds or abnormal hot spot patterns emerge, thereby gaining critical response time.

5) Building Inspections: Making Heat Loss Visible: Making the Invisible Visible

In the field of building energy efficiency and diagnostics, passive thermography provides a clear visual representation of heat loss occurring in building exterior walls, doors, windows, and roof structures.

Typical passive thermography applications for building inspections include:

· Exterior wall insulation performance assessment: identifying insulation gaps, construction defects, and thermal bridge locations

· Window and door frame seal integrity checks: observing cold air infiltration and heat leakage points through temperature distribution patterns

· Roof leak and moisture damage detection: recognizing that wet areas exhibit different thermal characteristics compared to dry ones, making judgments based on thermal image patterns

For building operations and maintenance teams, passive thermography provides a non-destructive and large-area diagnostic method that helps develop more targeted energy-saving and maintenance plans.

3. Active Thermography: Excitation-Based Inspection for Fine Defects

Active thermography is widely employed as a non-destructive testing (NDT) technique. It applies external energy to the target, creating controlled thermal changes, then uses thermal cameras to observe how thermal waves propagate and attenuate through material, thus revealing internal defects.

Typical external excitation methods include:

· Optical excitation: using flash lamps, halogen lamps, or lasers to produce short-duration or periodic heating (pulsed thermography, lock-in thermography)

· Convective heating: using hot air streams to heat the target surface, then analyzing the temperature distribution during cooling

· Ultrasonic or mechanical excitation: generating local heating within the material through methods like ultrasonic vibration, then capturing this thermal difference by thermal imaging

In active thermography, the focus shifts to “dynamic thermal response”—regions that cool more slowly or heat more rapidly often correlate with internal voids, disbonds, or cracks.

For components immediately after welding, brief external heating reveals internal defects such as porosity, cracks, and slag inclusions by observing heat propagation patterns. In composite materials, pulsed thermal excitation identifies delamination and debonding. Such applications are increasingly common in aerospace and automotive industries where material integrity is critical.

4. Active Thermography vs. Passive: Understanding Key Differences

From a practical engineering perspective, the distinction between active and passive thermography reflects different usage strategies rather than fundamentally different hardware. The same infrared camera, when paired with different external excitation and data processing software, can perform both passive and active thermography.

Dimension | Passive Thermography | Active Thermography |

Heat source | Natural thermal radiation emitted by the object under actual operating conditions | External energy (light, heat, ultrasound) applied to the object to create controlled thermal change |

Focus of analysis | Surface or near-surface temperature distribution and static hot spots | Internal defect effects on thermal wave propagation; emphasis on dynamic processes |

Typical application scenarios | Power grid inspections, industrial equipment monitoring, security surveillance, building energy audits, fire early warning | Aerospace composites, weld quality assessment, adhesive bond inspection |

System complexity | Relatively simple; typically only the thermal camera and appropriate optics needed | Higher; requires controlled excitation source, synchronized acquisition, and specialized data processing algorithms |

Deployment and cost | Easy to deploy or use; suited for large-area inspection and continuous online monitoring; lower total cost | Demanding deployment conditions and extensive commissioning; typically reserved for lab or dedicated inspection stations |

Detection speed | Fast inspection; enabling rapid scanning of many assets or large areas | Detection time constrained by excitation and processing; slower measurement cycle |

User expertise required | Requires operational skill and image interpretation training, yet readily teachable | Needs professional NDT background for system setup and result interpretation |

Standard thermal cameras typically operate in passive mode because most applications such as power, industrial, security, and building diagnostics have already contained sufficient natural temperature differences, eliminating the need for external excitation.

Therefore, for enterprises deploying thermal imaging solutions in these sectors, high-performance passive systems are typically more economical and easier to deploy; specialized active thermography systems are mainly reserved for high-end NDT applications requiring internal defect detection.

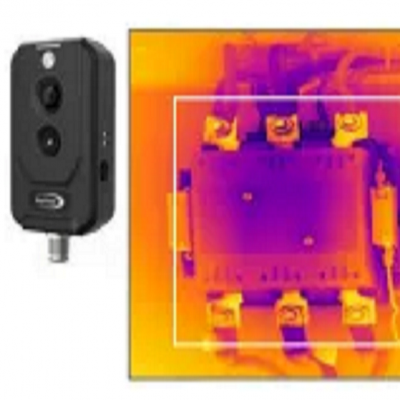

5. Raythink Passive Infrared Camera Recommendations

Raythink’s passive infrared cameras employ uncooled VOx detectors and advanced image processing algorithms to deliver clear and accurate thermal images under diverse environmental conditions. Our products offer core advantages including real-time temperature monitoring, non-destructive testing capability, and all-weather operation.

PD464T Dual-Spectrum Speed Dome Camera

FC465T Dual-Spectrum Bullet Camera

RM620 Handheld Thermal Camera

TN220 Thermographic Cube Camera

6. Conclusion

Passive and active thermography address different application needs rather than competing on which is more advanced. High-performance passive thermal imaging systems achieve the best balance among deployment cost, ease of use, and practical value, making them the preferred choice for most industrial and security applications. Raythink specializes in passive infrared thermal imaging solutions customized to the real operating conditions of different industries. Contact Raythink’s expert team for professional guidance on system selection and deployment.

Recently Posted

-

TN220 Thermographic Cube Camera: Cigarette Pack-Sized Infrared Device Unlocks New Safety Monitoring

February 4, 2026In the field of industrial safety monitoring, three core pain points have long plagued operation and maintenance teams: difficulty Read More

Read More -

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More