How Thermal Imaging Cameras Improve Vehicle Safety Inspections

Introduction

As the global new energy vehicle industry accelerates its development, the high-voltage, high-current technical approach not only shortens charging times but also imposes stringent requirements on safety inspections throughout the vehicle’s entire lifecycle. Simultaneously, the structure of traditional fuel-powered vehicles is undergoing intelligent and integrated upgrades, which continuously increases the difficulty of inspecting core components such as engines, braking systems, and electrical circuits.

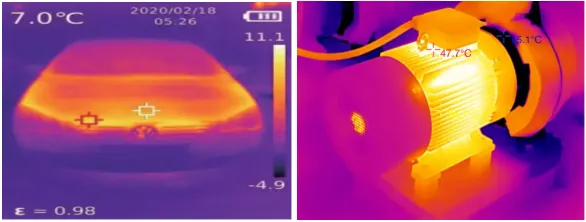

Traditional inspection methods, relying on manual experience and contact-based measurements, are not only inefficient but also struggle to detect potential safety hazards like temperature anomalies or hidden fluid leaks. Infrared thermal imaging cameras, leveraging their core advantage of “visualized temperature measurement,” have emerged as the key tool to address these pain points in vehicle safety inspection.

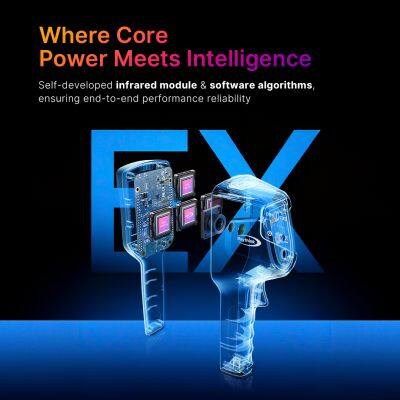

1. Key Advantages of Infrared Thermal Imaging Cameras

Infrared thermal imaging cameras capture infrared radiation emitted by objects and convert it into temperature images, overcoming the limitations of traditional inspection methods. Their key advantages precisely align with the practical demands of vehicle safety inspection, making them a core driver for industry advancement.

1) Non-contact Inspection

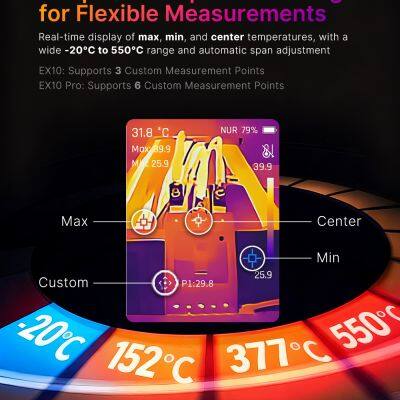

Vehicle core components such as engine blocks, battery packs, and brake discs often operate under high-temperature and high-pressure conditions. Contact-based measurement is not only hazardous but may also damage precision parts. Raythink thermal imaging cameras employ non-contact temperature measurement principles, acquiring precise thermal data without physical contact. For instance, the AT61Motorized Focusing Thermal Camera for temperature measurement enables wide-range temperature detection from -20°C to +550°C. In automotive friction welding monitoring, it remotely captures real-time weld point temperatures, eliminating interference with the welding process and ensuring optimal weld quality reaches the optimal state.

2) Real-Time Monitoring of Temperature Anomalies

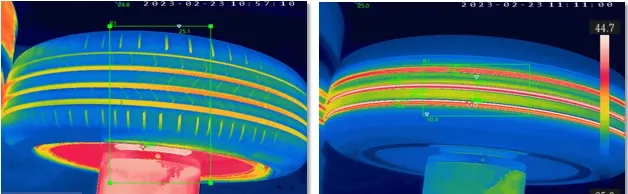

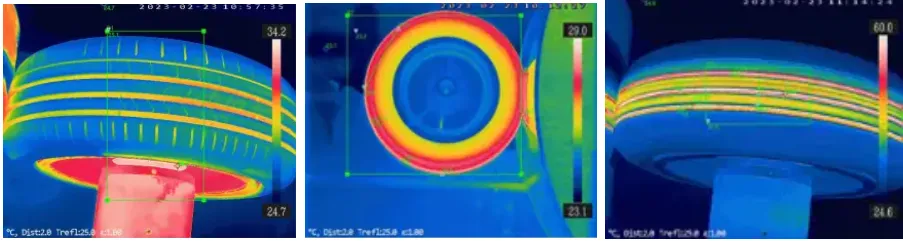

Temperature anomalies serve as critical precursors to vehicle failures. Issues like tire overheating and blowouts, battery thermal runaway, or circuit overloading and heating manifest through temperature changes. Thermal imaging cameras swiftly detect subtle temperature fluctuations, enabling early warning. Certain statistical data indicate that nearly half of highway accidents stem from tire failures, particularly during summer heat when high-frequency friction between tires and the ground can cause high-temperature blowouts. Raythink thermal imaging cameras visually display tire surface temperature distributions, accurately reflecting operational conditions and providing critical data support for R&D testing and routine inspections.

3) New Energy Vehicle Adaptation

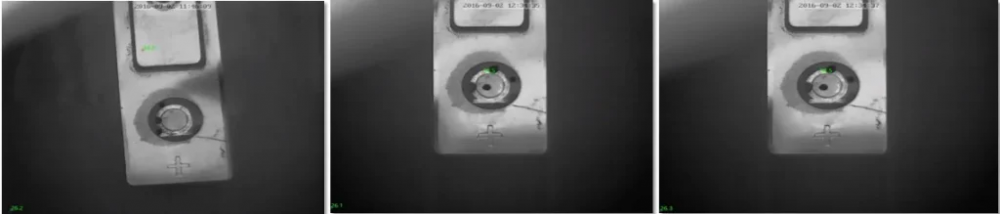

Core components of new energy vehicles—such as battery packs, motors, and electronic control systems—feature complex structures and demand stringent safety standards. Traditional inspection methods struggle to visually identify hazards like battery leakage or structural insufficient soldering. Thermal imaging cameras, however, leverage the distinct infrared characteristics of different materials to efficiently detect faults. For battery pack leakage detection, the Raythink TN460 Fixed-mount Thermal Camera captures temperature anomalies caused by leaks, rapidly pinpointing their location and extent. This approach significantly enhances detection efficiency and accuracy compared to traditional methods like resistance testing or pressure testing.

4) Data Traceability

Raythink thermal imaging products support real-time transmission and storage of temperature data. Equipped with Gigabit network interfaces and multiple protocols including ONVIF and GB28181, they seamlessly integrate into backend systems. In applications such as factory inspection of lithium batteries for new energy vehicles, they enable automated temperature measurement and data logging, replacing manual reporting and data entry. This not only reduces errors but also generates comprehensive inspection records, providing reliable evidence for quality traceability.

2. Typical Application Scenarios

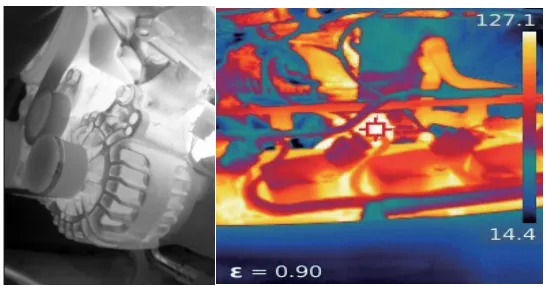

1) Engine and Powertrain Inspection

Temperature distribution across engine components like cylinder blocks, pistons, and valves directly impacts performance and reliability. Traditional disassembly or indirect measurement methods often struggle to detect latent faults. Infrared thermal cameras capture real-time temperature images of components during engine operation. By identifying localized overheating or undercooling zones, they rapidly pinpoint issues like cylinder wall wear and micro-component failures. Inspections can utilize handheld devices or bench-mounted imagers for comprehensive scanning without disassembly. This approach prevents damage to precision components while significantly boosting troubleshooting efficiency, providing data-driven support for maintenance and R&D optimization.

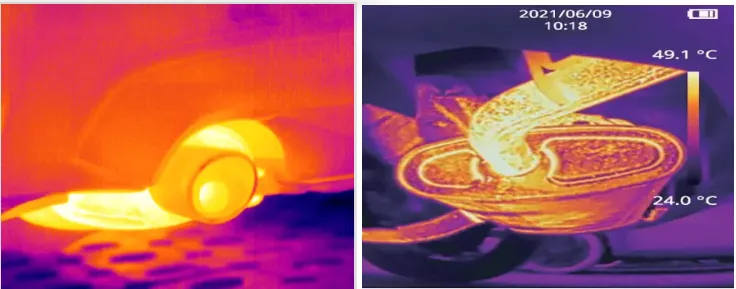

2) Brake System Inspection

Temperature changes in brake pads and rotors directly reflect braking performance and wear status, serving as critical safeguards for driving safety. After continuous braking, a sharp rise in brake pad temperature may indicate reduced braking effectiveness due to excessively soft friction material. Conversely, a gradual temperature increase could signal accelerated rotor wear from overly hard material, potentially leading to emergency braking failure. Infrared thermal imaging cameras enable real-time monitoring of temperature distribution across brake pads, calipers, and brake humps during braking. They visually capture abnormal heating or uneven temperature patterns, facilitating rapid identification of potential faults and preventing safety incidents caused by brake system failures.

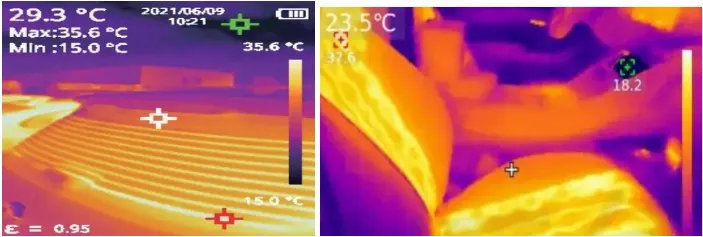

3) Tire and Chassis Safety Inspection

Tire surface temperature directly correlates with tire pressure, traction, and wear. High temperatures can cause increased tire pressure and accelerated wear, while low temperatures reduce traction, leading to handling difficulties or slippage risks. Infrared thermal imaging cameras precisely capture tire surface temperature distributions, providing real-time insights into operational conditions. This data supports material selection during R&D testing and aids in identifying potential hazards during routine inspections. Additionally, thermal imaging can promptly detect abnormal temperatures in chassis suspension systems, drive shafts, and other components, helping prevent structural fatigue failures and ensuring driving stability.

4) Exhaust System Inspection

Excessive exhaust pipe temperatures can compromise engine systems, chassis bearings, and electrical equipment safety. Uneven temperature distribution may also indicate structural defects in piping or incomplete fuel combustion. Infrared thermal imaging enables non-contact monitoring of exhaust pipe temperature variations, rapidly locating abnormal hotspots and leaks. This facilitates indirect assessment of engine performance, preventing vehicle performance and safety issues caused by exhaust system failures.

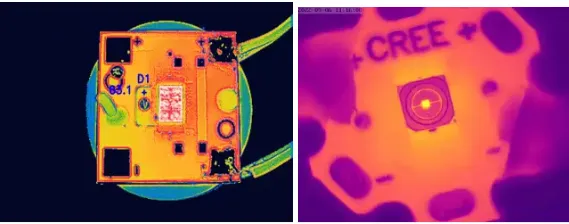

5) Electrical and Battery System Inspection

· New Energy Vehicle Battery-Related Inspection: Power battery packs are susceptible to thermal runaway due to external impacts, electrical misuse, or quality issues, posing fire and explosion risks. During battery maintenance and factory testing, thermal imaging cameras monitor temperature anomalies preceding thermal runaway, enabling early warning and intervention to prevent thermal runaway. For battery pack leakage issues, leveraging the distinct infrared characteristics of different liquids, thermal imagers capture temperature variations caused by leaks to rapidly pinpoint leakage locations and extent. This approach significantly enhances efficiency and accuracy compared to traditional methods like resistance testing or pressure detection.

· Traditional Vehicle Electrical Testing: Faults in electrical components such as automotive glass heating wires, seat heating elements, and high-voltage circuits often manifest through temperature changes. Infrared thermal imaging provides a clear view of the temperature distribution during windshield heater wire operation, identifying issues like wire breaks or uneven heating to prevent glass shattering from localized overheating. For seat heating failures, it swiftly pinpoints damaged heating elements or poor wiring connections, reducing repair costs. It also detects localized heating caused by aging insulation or loose connections in high-voltage wiring, eliminating short-circuit fire risks.

6) Body Accessories Inspection

· Air Conditioning & Air Leak Detection: When cooling or heating performance is poor, thermal imaging cameras pinpoint issues like clogged air conditioning pumps, blocked condensers, or refrigerant leaks. By monitoring cooling effectiveness at vents, they assist in optimizing repairs. They also swiftly locate air leaks in the body structure, ensuring efficient air conditioning system operation.

· LED Headlight Inspection: LED headlights comprise dozens to hundreds of individual light-emitting diodes (LEDs), making individual defects difficult to discern visually. An infrared thermal imager with a macro lens enables intuitive assessment of LED operational status based on thermal distribution, promptly identifying defective LEDs while analyzing luminous efficiency to ensure driving illumination safety.

7) Automotive Manufacturing Process Monitoring

· Hot Riveting and Die Casting Processes: During dashboard frame hot riveting, thermal imaging camera monitors real-time temperature distribution to ensure uniform heating, preventing localized overheating or insufficient heating. It intelligently coordinates with heating equipment to optimize process parameters and reduce energy consumption. For die casting mold inspection, it monitors mold temperatures before/after casting and post-water-cooling, enabling full production line automation via PLC integration. This records comprehensive production temperature data to guarantee component quality.

· Glue Application Process: During automotive glue application, environmental temperature fluctuations and production line stoppages can cause abnormal nozzle temperatures, leading to quality issues like missed application or glue buildup. Online thermal imaging cameras provide 24/7 automated monitoring of nozzle temperatures, eliminating manual inspections, ensuring process stability, and preventing vehicle quality risks.

8) New Energy Charging Station Monitoring

High-voltage, high-current operations expose charging station components—including connectors, wiring, and distribution boxes—to overheating risks. Raythink dual-spectrum thermal cameras (e.g., FC series, PD225T) enable 24/7 uninterrupted monitoring. Through multi-level temperature measurement settings (point, line, area), they precisely track critical zones. Upon detecting temperature anomalies, the system triggers real-time audible and visual alarms while activating fire suppression equipment to prevent fires before they start. Remote monitoring via mobile apps enables staff to receive alerts anytime, anywhere for immediate hazard resolution. Compatible with GB28181-2016, ONVIF, and other protocols, it supports networked management of thousands of channels to meet safety requirements for large-scale charging stations.

3. Raythink Product Recommendations

Addressing diverse vehicle safety inspection needs, Raythink offers multiple high-performance thermal imaging cameras covering the entire lifecycle from R&D testing to production maintenance. Their precise, efficient, and stable performance has earned market recognition.

1) RM620 Handheld Thermal Camera

· 640×512 infrared resolution, 35mK high thermal sensitivity

· -20℃~+650℃ wide temperature measurement range

· Dual-spectrum fusion imaging with voice/text annotation and video recording

· IP54 protection + 2m drop resistance, ideal for mobile scenarios like auto repair and battery inspection

2) AT61 Motorized Focusing Thermal Camera

· 640×512 infrared resolution, high-definition thermal vision

· -20℃ to +550℃ wide temperature measurement range

· Gigabit network interface supports multiple protocols including RTSP and ONVIF for seamless system integration

· Motorized focus design, ideal for tire testing, welding monitoring, and similar applications

3) TN460 Fixed Mount Thermal Camera

· 640×512 infrared resolution, high-definition imaging

· -20°C to +650°C wide temperature measurement range

· 25Hz frame rate ensures synchronized temperature and image data

· Rich interfaces support SDK development for easy integration

· Compact, low-power design with multiple lens options ideal for new energy vehicle battery pack inspection and leakage detection

4) FC Series Dual-Spectrum Bullet Camera

· Infrared resolution options: 256×192/384×288/640×512, temperature range -20℃~550℃, accuracy ±2℃ or ±2% of reading

· Dual-spectrum fusion technology supports intelligent behavior analysis including fire detection, intrusion detection, and perimeter crossing detection, enabling integrated security and fire monitoring

· Supports point, line, and area temperature measurement rules, enabling multi-level alerts for critical zones like charging port interfaces and wiring

· Operates 24/7 in all weather conditions, ensuring uninterrupted detection regardless of darkness or harsh environments

· Widely applied in indoor/outdoor security, fire prevention, and equipment temperature monitoring scenarios, delivering multi-functional cost savings

5) PD225T Network Speed Dome Camera

· Temperature measurement range: -20°C to +550°C. Supports four temperature measurement modes: full-screen, point, line, and area. Accuracy: ±2°C or ±2%.

· 360° continuous rotation scanning with adjustable speed (0.1°–120°/s). Supports preset point patrol temperature measurement for extensive coverage.

· Built-in smoke/fire detection and AI-powered human/vehicle recognition algorithms enable real-time identification of fire hazards and intrusion targets while minimizing false alarms

· Supports ONVIF protocol and SDK development for seamless integration with NVR/VMS software, enabling unified management

· IP66 protection rating with operating temperature range -40°C to +70°C, suitable for harsh industrial environments

Conclusion

As the core tool for “visualized temperature measurement,” thermal imaging cameras overcome the limitations of traditional detection methods. With their non-contact, real-time, and data-driven advantages, they have become a critical pillar for ensuring vehicle safety throughout their entire lifecycle.

Raythink offers multiple high-performance products tailored for vehicle safety inspection. From R&D testing to production operations, from traditional fuel vehicles to new energy vehicles, and from the vehicles themselves to charging infrastructure, we provide comprehensive, scenario-based inspection solutions.

Moving forward, Raythink will remain innovation-driven, integrating AI and multi-dimensional sensing technologies to continuously enhance product performance and solution adaptability. We are committed to energizing the global vehicle safety inspection industry, safeguarding safety and efficiency during the entire vehicle lifecycle operation.

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More