Making the Invisible Visible: Latest Thermal Imaging Solution for 3D Gas Leak Detection

According to Markets and Markets™, the Gas Detection Market is expected to reach USD 5.18 billion by 2030, from USD 3.84 billion in 2025, due to increasing industrial safety standards, stricter regulatory compliance and a growing emphasis on environmental protection. In response, the industry is developing innovative gas detection technologies to meet this rising demand. Among these, the OGI camera (Optical Gas Imaging Camera) stands out as one of the most accurate instruments, offering touchless, long-range and three-dimensional gas visualization.

Raythink, a leader in thermal imaging technology, is driving innovation in gas detection. By integrating advanced OGI cameras with AI-powered algorithms and a comprehensive software platform, Raythink provides higher performance, integrated solutions that help industries improve safety, ensure regulatory compliance, and reduce environmental negative impact.

1. What is an OGI camera?

An OGI camera (Optical Gas Imaging Camera) is a specialized device that uses infrared imaging technology to detect gas leaks visually. It allows operators to identify and locate gases that are invisible to the naked eye, such as methane, volatile organic compounds (VOCs), sulfur hexafluoride and other hazardous gases.

2. How does an OGI camera work?

Industrial hazardous gases (e.g., methane, VOCs, and ammonia) exhibit characteristic molecular vibrational and rotational absorption spectra in the certain infrared range of 3–17 μm. When infrared radiation passes through these gases, the gas molecules absorb energy at their characteristic wavelengths, resulting in wavelength-specific absorption features.

Building on this principle, when a dynamic gas leak occurs within the field of view of an OGI camera, it produces dynamic radiation differences at the corresponding absorption wavelengths, which appear as grayscale contrast in the infrared image. The higher the gas concentration, the stronger the absorption, and the more pronounced the grayscale contrast.

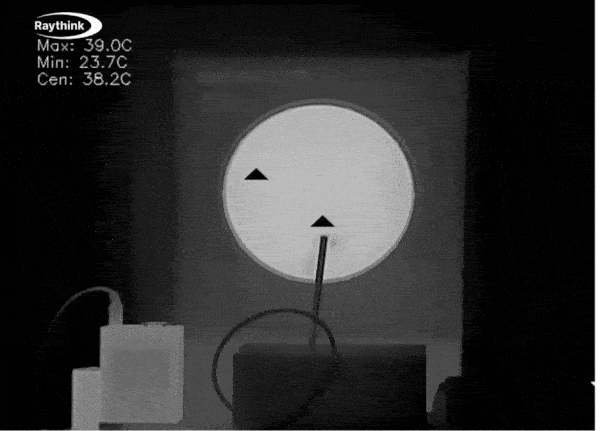

SF6 leak visualization using thermal imaging

3. Why Choose OGI Technology for Industrial Gas Detection?

Compared to other instruments like fixed gas detectors, portable gas detectors and gas analysers, the OGI camera has multiple advantages:

· Visualization

OGI cameras can directly display the shape, direction, and dispersion of gas plumes through infrared imaging, which is their most significant advantage over traditional gas detectors. When a conventional gas detector triggers an alarm, operators still need to manually confirm whether the alarm is real or a false positive and then search point by point to locate the leak. In contrast, OGI cameras instantly show the leak visually, allowing operators to quickly identify its exact location, assess its severity, and take immediate action.

· Non-contact

Timely gas detection is critical because many industrial gases are toxic, flammable, or otherwise hazardous. Traditional detection methods, such as portable gas detectors, often require operators to approach potentially dangerous areas to locate leaks, exposing them to safety risks. OGI cameras, however, allow operators to identify and assess gas leaks from a safe distance visually, eliminating unnecessary exposure while providing accurate and immediate information for maintenance or emergency response.

· High Efficiency

Compared to point-based instruments, the OGI camera improves gas detection efficiency significantly by enabling rapid, large-area scanning within seconds. Additionally, it can visualise multiple gases within its spectral range without the need to switch sensors or change equipment, thereby further streamlining inspection workflows.

4. From Points to 3D Gas Detection

Single-point inspection and distributed sensor networks are two conventional approaches to detect gas leak. Still, both are limited by fixed coverage patterns and cannot independently achieve full-area, real-time monitoring. To overcome these limitations, the current trend is to combine multiple complementary detection methods across three-dimensional space to gain a comprehensive understanding of gas leak distribution.

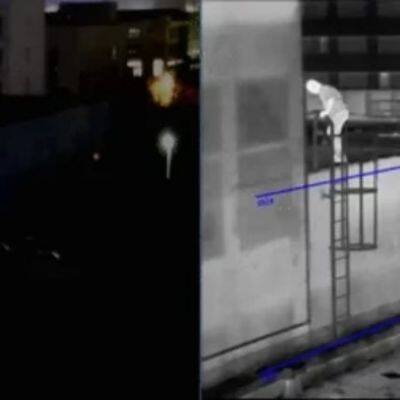

Point-based sensors continuously monitor critical locations, such as pipe joints and storage tanks, providing early warnings of potential leaks. Fixed OGI cameras provide 24/7 visual monitoring, revealing the shape, direction, and spread of gas plumes without exposing personnel to hazards. Handheld and drone-mounted OGI devices allow flexible inspections, precise leak localization, and access to hard-to-reach areas.

All data from sensors, cameras, and drones is integrated into a centralized platform for smart analysis and real-time alerts. This multi-source approach enhances situational awareness, reduces false alarms, and enables faster, safer responses to leaks.

5. Raythink: Empowering Industrial Gas Detection

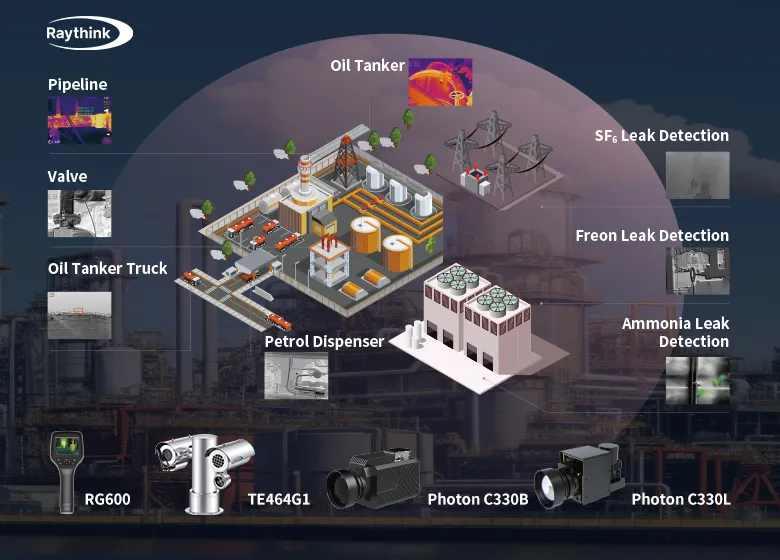

As an innovator in thermal imaging technology, Raythink offers a comprehensive series of OGI cameras to meet diverse industrial gas detection needs.

Raythink’s thermal imaging solutions for industrial gas detection

· Fixed OGI Cameras

Raythink’s TE464G1 Explosion-Proof Gas Imaging PTZ Camera is an ideal solution for continuous 24/7 monitoring of high-risk areas such as pipelines, storage tanks, and chemical processing units. Equipped with a highly sensitive uncooled infrared detector (NETD ≤ 20 mK), dual-spectrum imaging (infrared + visible), and full PTZ coverage, TE464G1 can automatically patrol large industrial zones, visualize gas plumes, detect leaks in real time, and integrate with plant monitoring systems for automated alerts. Its dual explosion-proof certification and IP68-rated enclosure ensure safe and reliable operation even in hazardous environments.

· Handheld OGI Cameras

For routine inspections and rapid leak localization, Raythink offers handheld OGI cameras for efficient on-site detection. The RG600 Series enables operators to identify hundreds of industrial gases, including SF₆, methane (CH₄), and VOCs, from distances of up to 20 meters. Its portable, rugged design makes it ideal for spot-checks, maintenance inspections, confined-space checks, and quick verification of alarms in oil & gas, chemical plants, and industrial facilities.

· OGI Camera Module

For system integrators and equipment manufacturers, Raythink provides high-performance cooled OGI camera modules such as the Photon C330B and Photon C330L. Built with an MCT cooled infrared focal plane array and operating in the 3.2–3.4 µm spectral band, these modules deliver exceptional detection sensitivity (NETD ≤ 10 mK) and fast 25 Hz frame rate, making them highly effective for visualizing low-concentration VOCs. With optional fixed-focus and continuous-zoom lenses, the modules can be adapted to multiple industrial scenarios—from stationary monitoring systems to mobile inspection devices.

AI-Powered Algorithms & Smart Software Platform

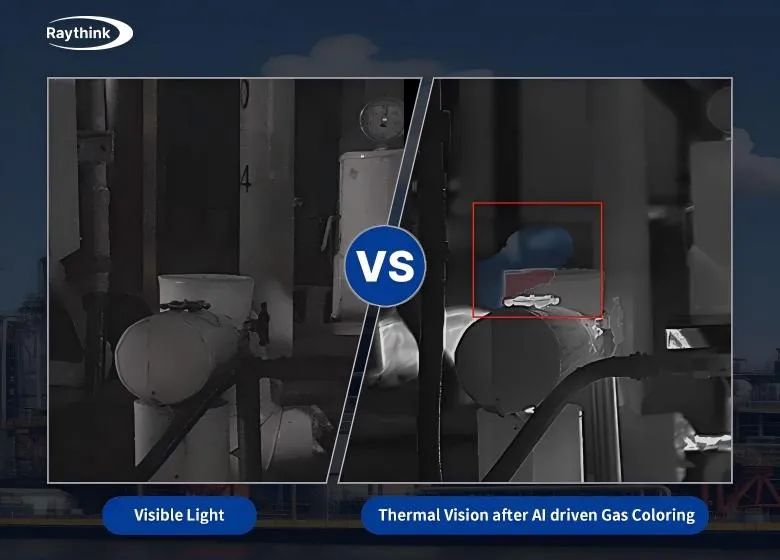

To further enhance the intelligence of industrial gas monitoring, Raythink is actively advancing a whole stack of AI technologies purpose-built for OGI applications. Raythink has developed proprietary algorithms that significantly improve gas recognition accuracy and introduced AI-driven plume visualization technology. By modeling both the background and gas-specific grayscale features, the system can precisely extract the shape and movement of gas plumes and automatically apply color based on concentration levels, delivering a more precise and more intuitive visualization of leaks.

Gas leak detection: Visible light vs. thermal vision after AI driven gas coloring

To complement its OGI cameras, Raythink’s VIS Patrol Gas software provides a comprehensive industrial gas monitoring platform. It integrates live video preview, infrared temperature measurement, and electronic map management with gas detection and pseudo-color visualization, allowing operators to see gas plumes in real time. The software offers configurable alarm parameters, including sensitivity and alarm filtering time. It supports alarm linkage for events such as gas leaks, fire points, and intrusions, automatically triggering sounds, snapshots, or IO outputs.

6. Applications of Raythink OGI Solutions

Raythink’s OGI technology and VIS Patrol Gas platform are applied across industries to address critical operational and safety challenges.

In oil and gas facilities, they help detect leaks before they escalate into fires or explosions. In chemical plants, they minimize unplanned shutdowns by rapidly identifying small leaks that could disrupt production. In storage and transport operations, they monitor volatile emissions to ensure environmental compliance and reduce regulatory risks. In power generation and electrical systems, these solutions enable the early detection of gas-insulated switchgear (GIS) and transformer leaks, thereby preventing costly equipment failures and maintaining grid reliability.

Across all applications, the system supports proactive risk management, improves maintenance planning, and enhances worker safety by providing actionable insights into gas behavior and leak progression.

By turning invisible gas leaks into visible plumes, thermal imaging technology enables precise, real-time detection and assessment of these leaks. Raythink’s OGI cameras and VIS Patrol Gas software provide industrial operators with the tools to act swiftly, minimize risks, and ensure safety in even the most challenging environments.

For More Information:

Email: sales@raythink-tech.com

Website: https://www.raythink-tech.com

Recently Posted

-

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More -

Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

January 22, 2026Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. D Read More

Read More