Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. During long-distance transportation, the uniformity and stability of the internal temperature of the refrigerated compartment directly affect the quality of goods. Especially for temperature-sensitive goods, temperature fluctuation may cause performance attenuation, deterioration and failure, resulting in significant economic losses. Therefore, it is of great significance to build a real-time, accurate and visual temperature monitoring system for the cold chain logistics industry.

1. Core Value of Monitoring

Thermal cameras can be installed at appropriate positions inside the refrigerated truck to capture real-time thermal images of the compartment, through which the temperature conditions in different areas can be clearly observed. If there is a local failure in the refrigerated truck’s refrigeration system, obvious high-temperature areas will appear in the thermal images. Drivers can promptly detect this through the connected monitoring terminal and take measures such as adjusting refrigeration parameters or stopping for maintenance, thus preventing goods from deteriorating due to excessively high local temperatures. The temperature data recorded by the thermal imager can be uploaded to the background system in real time, facilitating logistics managers to remotely monitor temperature changes during transportation and providing a basis for traceability of goods quality.

2. Application Scenarios

Refrigerated truck transportation covers temperature-sensitive items including food, pharmaceuticals, electronic products, and mechanical equipment. Temperature fluctuations may affect the quality or performance of these items.

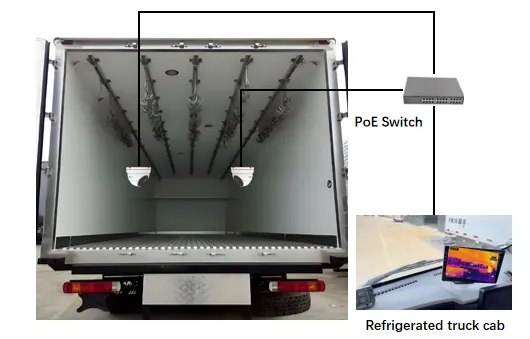

According to the size of the logistics truck, infrared dual-spectrum turret cameras or infrared dual-spectrum bullet cameras can be installed at the top corners inside the truck. Video and temperature information are transmitted to the refrigerated truck cab through a local area network (LAN) networking method.

3. Core Equipment Advantages

1) FC125T Dual-Spectrum Turret Camera

· Visible light & thermal imaging dual-spectrum

· ±2℃ industrial-grade temperature measurement accuracy

· Intelligent video analysis functions such as fire and smoke detection algorithm, area tripwire detection, and intrusion detection

· Multiple event-linked alarms and audio-visual alarms

2) Dual-Spectrum Bullet Camera FC2/FC4 Series

· Multiple infrared resolutions (640×512/384×288/256×192) to meet diverse scene requirements

· Intelligent analysis and alarm linkage capabilities.

Recently Posted

-

Advancing Smart City Safety: Raythink Unveils AI-Powered Security Tech at Intersec Dubai 2026

January 20, 2026Raythink Technology, an innovator in thermal imaging technology, is proud to showcase its latest security solutions at Inters Read More

Read More -

Raythink Infrared Thermal Imaging Technology: Building an All-Time and All-Round Forest Fire Prevent

January 20, 20261. Background and SolutionFrequent human activity in mountainous forest areas poses widespread fire hazards with fire sources that Read More

Read More -

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More