Why Can Thermal Cameras Be Used for Gas Detection?

1. Introduction: Principle of Gas Detection by Infrared

Thermal Imagers

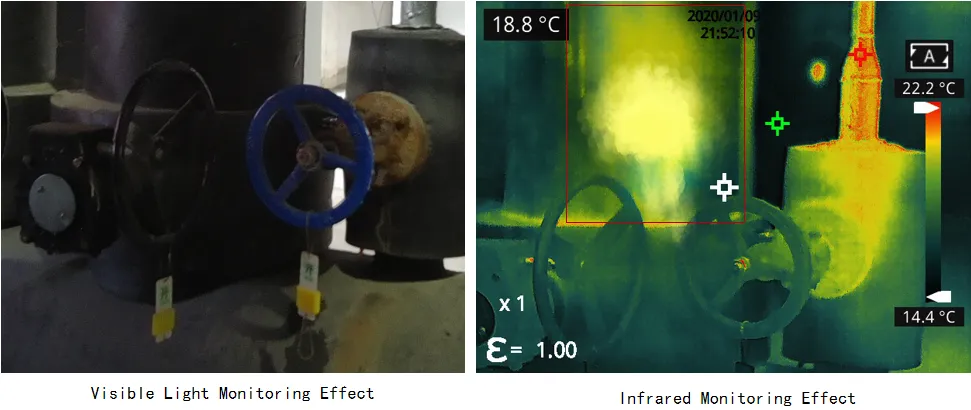

All objects with a temperature above absolute zero emit infrared radiation, and the intensity of this radiation is proportional to the object’s temperature. Infrared thermal cameras can convert invisible infrared radiation into visible infrared images through photoelectric conversion, thereby intuitively presenting the temperature distribution of the target area.

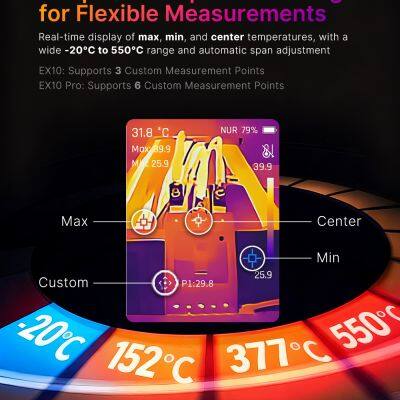

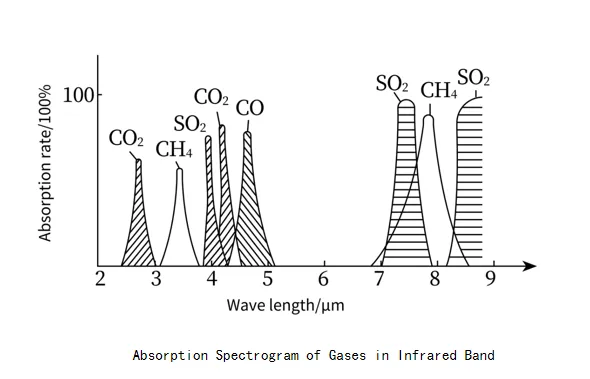

Gas molecules absorb infrared radiation in specific wavelength bands, and different gases have distinct absorption peak wavelengths. This creates an infrared radiation difference between the gas and the background. Based on this principle, Flint Technology’s gas imaging infrared thermal cameras adopt high-performance custom filter detectors to quickly identify infrared radiation differences absorbed by gases within characteristic wavelength bands. They convert invisible gases into clear.

2. Advantages of Gas Detection by Infrared Thermal

Imagers

1) Gas Visualization for Rapid Leak Trace Location

Infrared gas imaging technology converts invisible leaking gases into visual images, serving as an important tool for gas leakage detection. It helps operation and maintenance personnel quickly lock in leak points and achieve precise positioning of gas leakage locations.

2) Efficient Inspection for Cost Reduction and Efficiency

Improvement

Equipped with large-range and rapid scanning capabilities, it can complete detection in multiple areas within a short time, significantly improving inspection efficiency. Compared with traditional methods, it saves more labor input and operation and maintenance costs, helping build a more economical and efficient inspection and operation system.

3) 24/7 Online Monitoring for Uninterrupted Gas Detection

Online devices can realize 24/7 continuous monitoring, capturing abnormal gas leakage in real time and avoiding blind spots and omissions caused by inspection intervals in traditional manual inspections.

4) Non-Contact and Long-Distance Detection for Uninterrupted

Safety

It supports non-contact and long-distance detection, allowing operation and maintenance personnel to complete detection tasks without approaching high-risk areas, thus effectively reducing operational risks. In addition, the detection process does not affect the normal on-site operation, achieving a win-win situation of “safe inspection + non-intrusive operation”.

5) Reliable Data Support for Assisting Scientific Decision-Making

Detection results can be output in the form of images or videos, intuitively presenting the location and diffusion status of gas. This facilitates risk level assessment, assists in formulating scientific disposal plans, and promotes the intelligence and refinement of inspection decision-making.

3. Solutions

1) Combined Inspection of Online Gas Cloud Imagers + Handheld

Infrared Gas Imagers

A. Online Gas Cloud Imagers -Real-Time Gas Monitoring in Key Areas

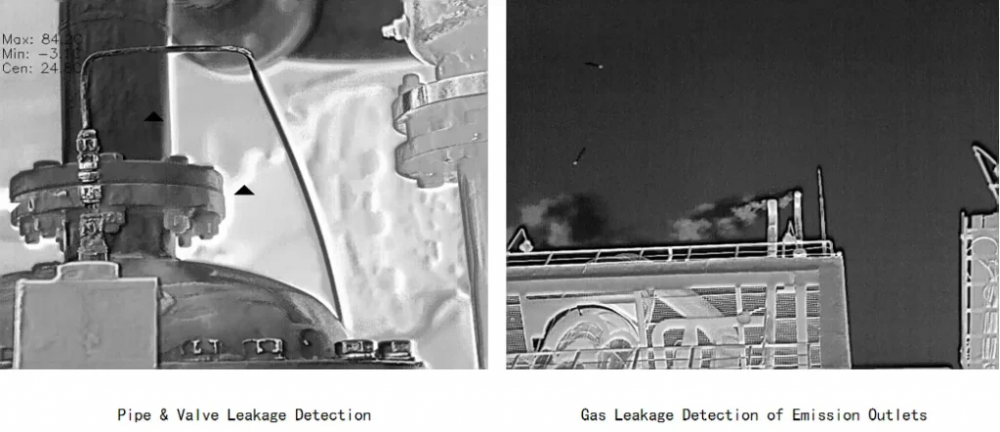

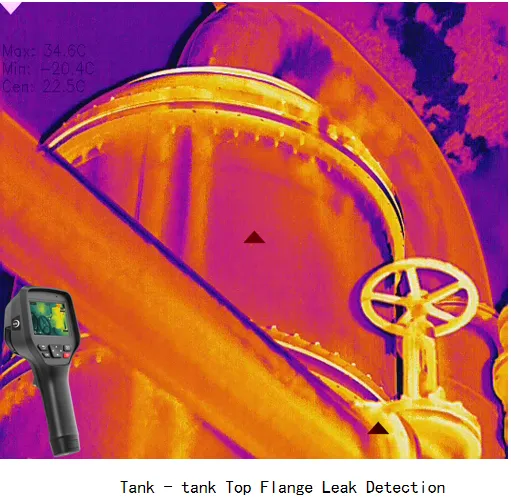

Install online gas cloud imagers at detection points in key areas to achieve real-time online detection. They enable intuitive, efficient, and safe visual inspection of critical components such as storage tanks, transport pipelines, valves, and flanges. This not only ensures the normal operation of equipment but also detects abnormalities and eliminates potential hazards. Combined with infrared and visible light sensing, it detects gas leaks and surrounding high-temperature safety hazards.

B. Portable Handheld Inspection-Comprehensive Gas Investigation and Precise

Reinspection

Professional personnel use handheld infrared gas imagers for large-area scanning and detection of the entire inspection area, with focused investigation of potential hazard points. This leaves no leak points undetected, allowing supervisors to quickly locate leaks and carry out maintenance and repairs.

2) Main Application Scenarios

Pipeline systems, storage tanks, valves and pipeline connections, pumps and compressors, reactors, distillation towers, and other equipment.

4. Recommended Products

Recently Posted

-

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More -

Why Use Thermal Imaging Camera for Heat Loss Detection

December 18, 2025In building energy management, heat loss is a critical factor affecting energy efficiency. Whether in residential, commercial buil Read More

Read More