How to Choose the Right Thermal Imaging Camera from China?

China has emerged as one of the most competitive sourcing destinations for thermal imaging cameras globally. With breakthroughs in infrared detector R&D, intelligent focusing algorithms, automated manufacturing, and supply chain optimization, Chinese thermal camera manufacturers now lead in both handheld and fixed thermal cameras. Beyond competitive pricing, they deliver superior measurement accuracy, system integration capabilities, and exceptional reliability—key advantages for global buyers seeking thermal imaging cameras from China.

Whether you require industrial inspections, electrical equipment monitoring, or production process control, selecting the right Chinese thermal imaging camera enables informed purchasing decisions. This guide explores competitive advantages, key selection criteria, and safe procurement practices for thermal cameras sourced from China.

1. Why Choose Thermal Imaging Cameras Made in China?

1) Significant Price Advantages

Chinese thermal cameras offer clear pricing benefits. Manufacturers operate comprehensive supply chains and scaled production systems, localizing everything from infrared detector chips and lens modules to final assembly. This vertical integration enables competitive pricing against Western counterparts without quality compromise. The advantage stems from mature manufacturing processes, efficient production models, and integrated supply chain infrastructure rather than reduced quality standards.

2) Diverse Product Portfolio

Chinese manufacturers provide extensive product lines spanning handheld and fixed thermal cameras, addressing everything from portable field inspections to fixed online monitoring. Buyers select configurations including resolution, focal length, temperature range, and communication interfaces based on specific applications, with software customization and OEM services available. This flexibility prevents over-investment and eliminates functionality gaps.

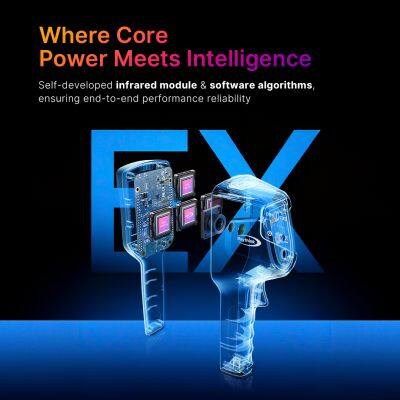

3) Rapid Technological Innovation

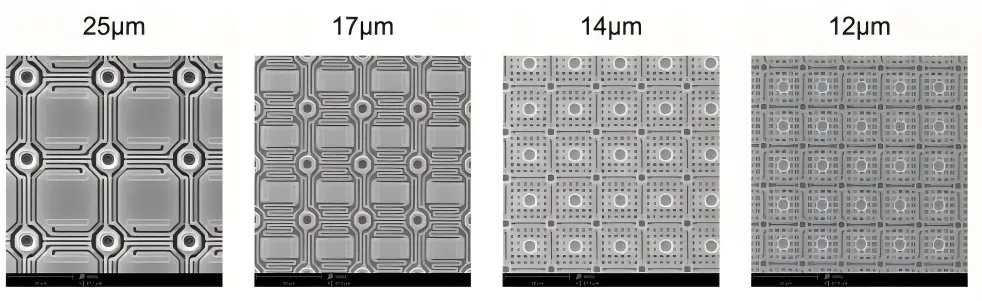

Chinese companies have achieved significant breakthroughs in core technologies, particularly in pixel miniaturization and AI algorithm integration. Leading manufacturers like Raythink now produce uncooled infrared detectors with 12μm pixel sizes and thermal sensitivity (NETD) reaching 25mK–40mK, substantially improving image clarity and measurement precision. Continuous advances in smart temperature analysis, trend recording, and anomaly detection meet diverse industrial inspection and preventive maintenance demands.

4) Complete Supply Chain Assurance

China maintains integrated thermal imaging industries from infrared detector chip production through final assembly. This vertical integration reduces costs while ensuring supply stability and rapid response capabilities. Logistics networks guarantee efficient delivery, typically requiring only 10–14 days from order confirmation to shipment.

2. Key Features to Evaluate When Selecting Thermal Imaging Cameras

1) Spectral Range and Application Matching

Long-wave infrared (LWIR, 8–14μm) remains the mainstream choice for thermal cameras, providing excellent atmospheric penetration and thermal radiation intensity suitable for most industrial inspection, electrical monitoring, and building diagnostics applications. Both handheld and fixed products adopt LWIR technology as standard.

LWIR detectors deliver high efficiency at ambient temperatures with relatively lower costs, providing optimal value. For specialized requirements, some manufacturers offer mid-wave infrared (MWIR, 3–5μm) or short-wave infrared (SWIR, 0.9–1.7μm) options for high-temperature metals or special material detection, though at premium pricing.

2) Resolution and Pixel Size

Resolution directly impacts image clarity and temperature measurement accuracy. Mainstream handheld and fixed thermal cameras offer resolutions from 256×192, 384×288, 640×512 to 1280×1024. Smaller pixel dimensions (like 12μm versus 17μm) enable higher spatial resolution, detecting subtle temperature variations and producing sharper thermal imagery in equivalent formats.

When selecting resolution, balance observation distance and application requirements. High-precision diagnostics and research applications benefit from 640×512 or higher resolution. Basic inspections like electrical maintenance adequately utilize 256×192 or 384×288.

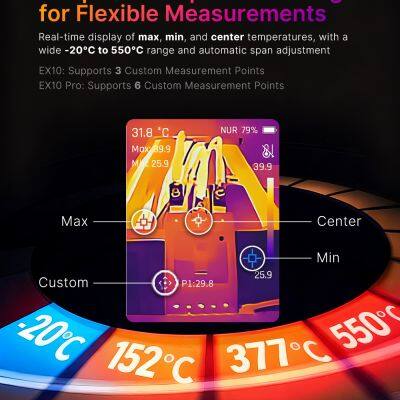

3) Temperature Measurement Range and Accuracy

Temperature measurement ranges vary by model specification. Handheld products typically cover –20°C to 150°C for ambient monitoring, with some extending to 100°C–550°C or 650°C. Certain fixed models reach –20°C to 650°C or even 0°C to 2000°C for ultra-high-temperature measurement. Switchable temperature ranges optimize accuracy across different operational conditions.

Measurement accuracy typically reaches ±2°C or ±2% of reading. Thermal sensitivity (NETD) serves as a critical performance indicator—mainstream products achieve NETD below 40mK, with premium models reaching 25mK–35mK. Smaller NETD values enable more precise temperature detection and finer imaging detail.

4) Detection Distance and Field of View

Detection distance depends on lens focal length, detector resolution, and target dimensions. Handheld products typically offer multi-focal-length options from 3.2mm to 60.9mm; fixed models provide selections from 4.1mm to 225mm. Longer focal lengths extend recognition distances but narrow the field of view (FOV); shorter focal lengths broaden the coverage area.

Ultra-wide-angle lenses (approximately 56°×42°) suit close-range broad coverage, standard lenses (approximately 25°×20°) balance distance and coverage, while telephoto lenses (approximately 7°×6°) enable long-distance precise monitoring.

5) Focusing Methods and Operational Convenience

Focusing options include fixed focus, manual focus, autofocus, and motorized focus mechanisms. Fixed focus suits close-range rapid inspection; manual focus provides precise imaging control; autofocus handles dynamic targets or variable distances; motorized focus in fixed models supports remote adjustment capabilities.

Premium handheld products support laser-assisted focusing, one-button center focus, single-touch autofocus, and continuous autofocus modes, significantly reducing operator error and improving on-site inspection efficiency.

6) Frame Rate and Dynamic Response

Frame rate represents the number of images captured and output per second. Handheld products typically operate at 25Hz or 30Hz; fixed models achieve 25Hz to 50Hz. Higher frame rates deliver smoother imagery, effectively capturing rapidly changing temperature data while preventing blurring or transmission delays—essential for real-time product line monitoring and dynamic process analysis.

Dynamic response also depends on signal processing speed and image algorithms. Rapid data refresh combined with efficient thermal signal processing maintains stable imaging in fast-changing environments.

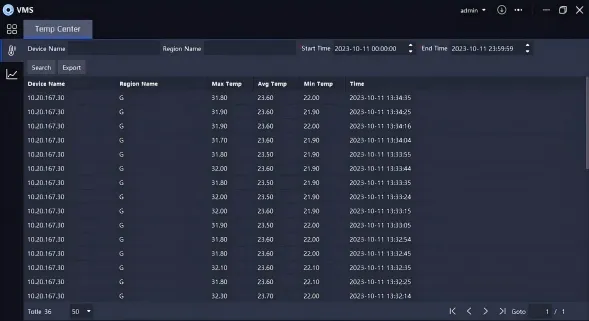

7) Communication Interfaces and System Integration

Handheld products typically include USB, HDMI, Wi-Fi, and Bluetooth interfaces; fixed models support RJ45 Ethernet, RS-485, USB, and HDMI. Mainstream products support standard protocols including ONVIF, GB28181, Modbus TCP, MQTT, and RTSP, enabling seamless integration with video management systems (VMS), network video recorders (NVR), and industrial automation platforms.

Some products also offer SDK packages and API interfaces supporting custom development and data sharing, meeting specialized system integration requirements.

8) Housing Quality and Durability

Most handheld products feature an IP54 protection rating (dust and splash resistant), pass 2-meter drop testing, and hold vibration resistance certifications with operating temperatures typically ranging from –10°C to 50°C or –20°C to 55°C. Fixed products typically achieve IP67 protection (complete dust resistance, temporary water immersion capability) with wider operating ranges reaching –40°C to 70°C.

Additionally, handheld devices often incorporate large-capacity rechargeable lithium batteries supporting 6–15 hours of runtime; certain models offer fast charging and hot-swappable battery options.

3. Raythink Popular Thermal Camera Recommendations

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More