Infrared Thermal Imaging: How Infrared Tech Boost Power Generation Security

1. Introduction: Status Quo of Electric Device Operation and Maintenance

The reduction in the number of power operation and maintenance personnel has led to an increase in the per capita workload, resulting in greater work intensity and longer hours. Consequently, management has become less efficient and comprehensive, making it difficult to meet the company’s requirements for high-quality development.

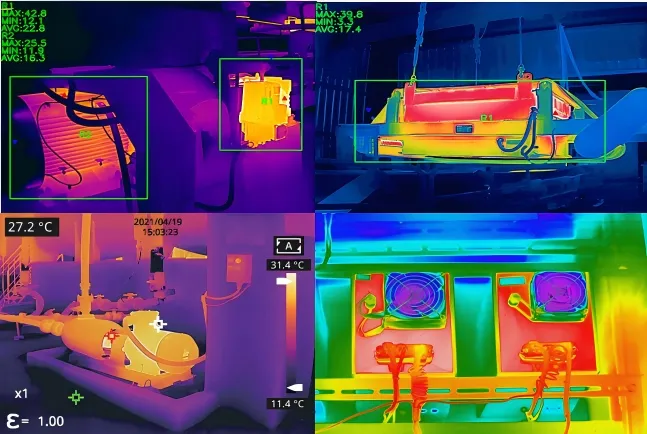

2. Infrared Thermal Imaging Application in Power Industry – Coal Storage/ Transportation

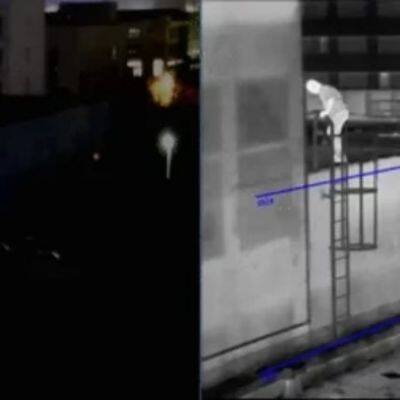

1) In coal storage yards, coal warehouses and other places, heating or even spontaneous combustion of coal piles may occur due to poor ventilation. Abnormal points can be detected at the smoldering stage of coal piles using a TE365 dual-spectrum explosion-proof bullet camera or TE464 dual-spectrum explosion-proof PTZ camera to eliminate the hazards.

2) During coal transportation via the conveyor belt, the belt is prone to tearing due to friction with foreign objects. To mitigate this risk, the FC series bullet camera can be installed above the conveyor belt. This setup allows for discovering the position of the belt with an abnormal temperature at the initial stage when the conveyor belt is worn to prevent further damage and avoid major economic losses.

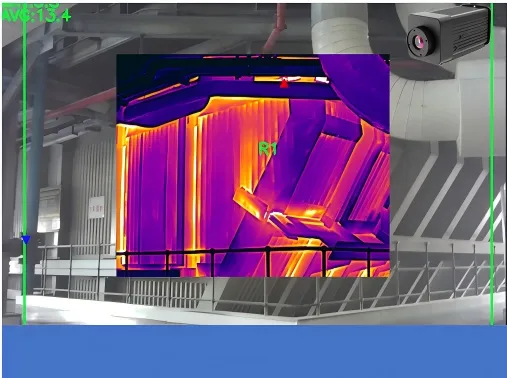

3. Infrared Thermal Imaging Application in Power Industry – Belt Conveyors and Magnetic Separators

It visualizes the device’s operating status, efficiently detects its thermal defects, provides real-time early warning of high temperature, and accurately locates faults to improve inspection efficiency.

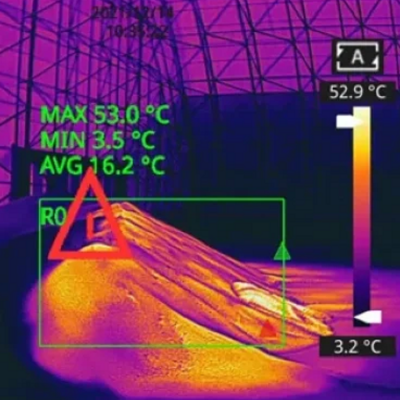

4. Infrared Thermal Imaging Application in Power Industry – Boiler Outer Wall

1) In the process of thermal power generation, the boiler is one of the most critical facilities and is key to achieving full power generation.

2) The AT31/61 motorized focusing thermal camera can be employed to monitor the boiler outer wall in real time. It detects localized “hot spots” on the wall to assess the boiler’s health status and timely detect wear, providing a visual reference for maintenance.

5. Raythink Thermal Imaging Equipment Recommendations

6. Conclusion

Infrared thermal imaging technology effectively addresses the challenges of inefficient manual maintenance in power generation systems. It enables early detection of hazards like coal pile smoldering, conveyor belt tearing, and boiler wall defects, enhancing inspection efficiency and accuracy. By replacing traditional manual checks, it reduces workloads for personnel, ensures stable operation of key equipment, and provides strong support for high-quality development of power companies.

Recently Posted

-

Passive vs. Active Thermography: How Thermal Cameras Enable Different Inspection Techniques

February 5, 2026In power grid inspections, industrial equipment maintenance, and security monitoring scenarios, thermal cameras have bec Read More

Read More -

TN220 Thermographic Cube Camera: Cigarette Pack-Sized Infrared Device Unlocks New Safety Monitoring

February 4, 2026In the field of industrial safety monitoring, three core pain points have long plagued operation and maintenance teams: difficulty Read More

Read More -

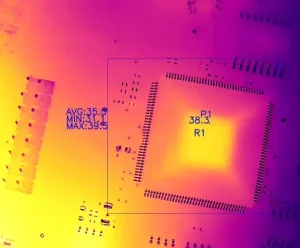

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More