Raythink Thermal Imagers: Precision Monitoring Solutions for Multiple Industrial Scenarios

In the core links of industrial production, temperature monitoring, explosion-proof security, and process control directly affect product quality, production efficiency, and operational safety. Traditional monitoring methods rely heavily on manual operations, featuring pain points such as cumbersome data recording, incomplete detection coverage, and poor adaptability to high-risk scenarios. Raythink’s thermal cameras—AT61 Motorized Focusing Thermal Camera and TE365 Dual-Spectrum Explosion-Proof Bullet Camera are respectively tailored to core scenarios including fiber laser factory inspection, and explosion-proof monitoring of electrolytic hydrogen production workshops. With advantages such as high-definition imaging, precise temperature measurement, and intelligent integration, they realize the upgrading of industrial monitoring towards automation, comprehensiveness, and safety.

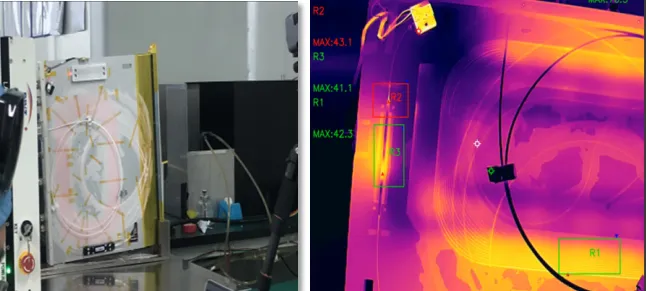

1. Infrared Thermal Camera in Industrial Fiber Laser Detection

Optical fiber lasers are widely applied, including laser optical fiber communication, industrial manufacturing, medical instruments and large-scale infrastructure fields. The user shall power on each device before delivery for testing, record the temperature of each component and identify defective products. The pain point of users is that it takes time and effort to manually report data and record to the background system when using handheld products for testing. In this project, images are clearly imaged by using the AT61 Motorized Focusing Thermal Camera, and then integrated into the background system through the camera interface, so as to realize the fully automatic factory temperature measurement.

AT61 Motorized Focusing Thermal Camera

· 640×512 infrared resolution, high-definition vision.

· Wide measurement range from -20°C to 550°C, suitable for multi-scenario applications.

· Gigabit network interface, supporting real-time transmission of temperature status.

· Multiple protocols such as ONVIF, for back-end integration.

· Motorized focusing, easy to operate.

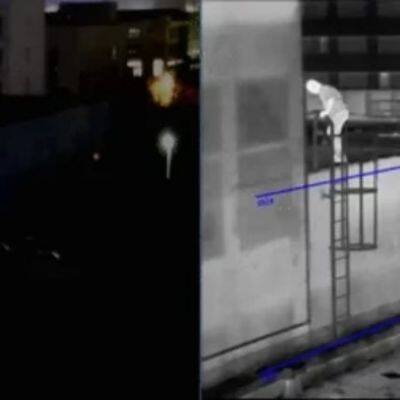

2. Infrared Monitoring in Electrolytic Hydrogen Production Workshop

For the workshop infrared monitoring scene with explosion-proof requirements, Raythink’s TE365 Dual-spectrum Thermal Imaging Explosion-proof Bullet Camera can be used. In this project, the electrolytic hydrogen production workshop shall be covered for infrared monitoring with abnormal high temperature alarm. At the front end, TE365 is mounted on a cross-arm bracket at a height of approximately 4 meters, obliquely covering and monitoring the workshop equipment. At the back end, Raythink’s networking monitoring software is used for 24/7 real-time infrared imaging and temperature measurement, and NVR video recording is also used.

TE365 Dual-spectrum Thermal Imaging Explosion-proof Bullet Camera

· Dual-spectrum imaging satisfies the 24/7 all-weather security monitoring requirements.

· Wide measurement range from -20°C to 550°C.

· Certified with dual explosion-proof ratings for dust and gas: Ex db IIc T6 Gb and Ex tb IIc T80°C D.

· Built-in intelligent smoke and fire detection algorithm.

· Supports VCA functions such as dual-spectrum region intrusion detection and tripwire intrusion detection.

Recently Posted

-

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

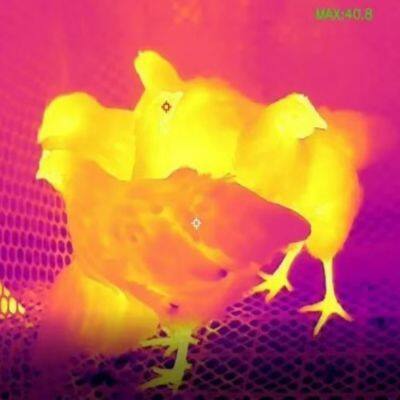

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More -

Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

January 22, 2026Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. D Read More

Read More