Batteries & Charging Piles: Infrared Thermal Cameras Safeguard New Energy Vehicles

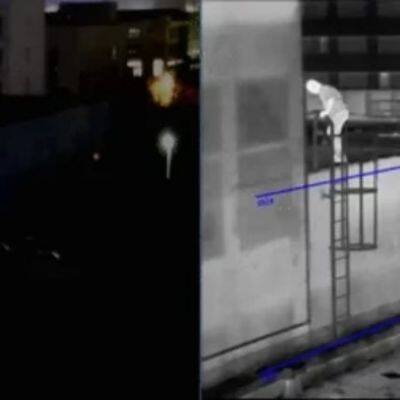

With the rapid development of the new energy vehicle industry, safety issues related to core components such as power batteries and charging piles have become the focus of industry attention. Potential hazards such as thermal runaway of power batteries, leakage of battery packs, and high-temperature overload of charging piles can not only lead to equipment failures but also trigger serious safety accidents such as fires and explosions, directly endangering the lives and property of occupants. Traditional detection methods either rely on post-event feedback or are difficult to intuitively locate hidden dangers, making it challenging to meet the safety needs of new energy vehicles for “early warning and early interception”. Infrared thermal cameras, with their technological advantages of 24/7 all-weather monitoring, non-contact temperature measurement, and visualized precise positioning, have become the core tool to address this pain point.

1. Temperature Monitoring of New Energy Vehicle Lithium Batteries

During the operation of power batteries, external mechanical impacts such as collisions, extrusions, punctures, and vibrations, electrical abuse, including external short circuits, overcharging, and over-discharging, as well as battery quality faults like internal short circuits, can cause thermal runaway of power battery packs, leading to safety issues such as battery fires and explosions. Therefore, to enhance the safety of power battery packs, infrared thermal cameras are used during battery pack maintenance to monitor, warn against, and mitigate thermal runaway, reducing the hazards associated with battery pack thermal runaway.

2. Leakage Detection of New Energy Vehicle Battery Covers

When the welding between the internal battery plates, tabs, poles, and busbars is insufficient, high-current discharge may cause arcing and ablation at the welding points, leading to battery explosions or leakage. Battery pack leakage is a critical issue related to battery safety and stability, which may result in reduced battery performance, damage, or even safety accidents. Currently, various methods are available for detecting battery pack leakage, including resistance detection, air pressure detection, VOC detection, mass spectrometry, and visual inspection, but none can provide intuitive and quick results. Infrared thermal cameras analyze and detect based on differences in the reflection, refraction, and scattering properties of infrared light by different liquids. When a battery leaks, the leaked liquid forms a distinct temperature difference on the battery surface. By capturing these temperature differences, infrared thermal cameras can efficiently and accurately identify the location and scope of battery leakage.

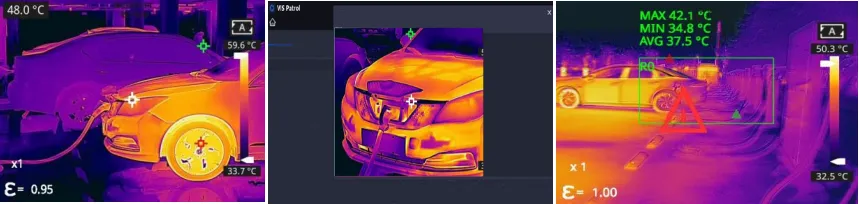

3. High-Temperature Early Warning Monitoring of New Energy Charging Piles

With the accelerated development of the new energy vehicle industry, charging piles generally adopt high-voltage and high-current operation modes to shorten charging time, placing higher safety requirements. Prevention is the top priority, only by detecting and controlling fires as early as possible can we minimize economic losses. Ordinary smoke detectors can only sense fires through smoke, at which point the fire has already begun to escalate. In contrast, thermal imaging equipment can issue alarms when temperature abnormalities occur, enabling the earliest detection of fire hazards.

Infrared thermal cameras conduct 24/7 online visual temperature monitoring of charging piles. Before an accident occurs, they issue early warnings based on temperature changes on the surface of charging interfaces and lines upon detecting abnormal temperature fluctuations, ensuring safe operation. It supports custom point, line, and area temperature measurement: multiple monitoring areas can be drawn according to monitoring targets for high-temperature hazard zones such as connecting cables, chargers, contact points, and distribution boxes, with multi-level early warnings for key areas enabling the prompt detection of potential high-temperature risks.

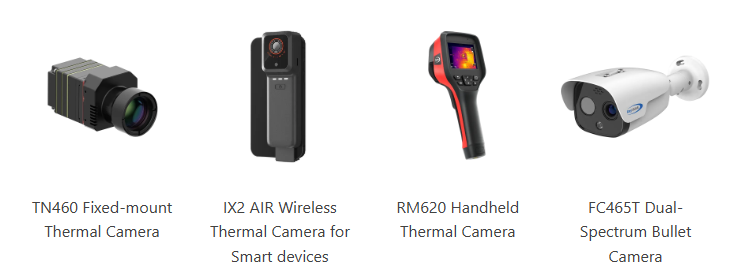

4. Raythink’s Product Recommendations

Recently Posted

-

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

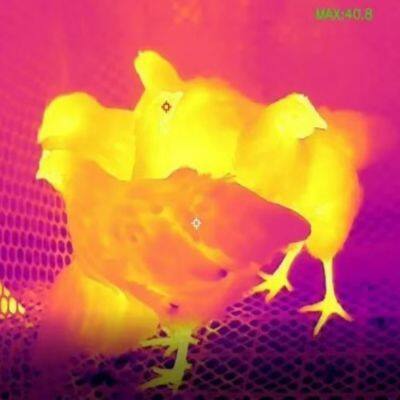

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More -

Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

January 22, 2026Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. D Read More

Read More