Application of Gas Detection Camera in Methane Leak Detection

Gas leaks not only threaten production safety but also harm the environment, potentially leading to fires or explosions that endanger lives and property. Methane (CH4)—the main component of natural gas and the second largest anthropogenic greenhouse gas after carbon dioxide—is colorless, odorless, and highly flammable, making methane leak detection critically important.

Traditional detection methods rely largely on point sensors, which struggle to provide comprehensive coverage. In contrast, thermal imaging gas leak detection technology enables wide-area, long-distance surveys that visualize leaks in real time. This allows rapid localization of gas leakage sources and dynamic visualization of gas plumes, becoming an efficient and modern solution for methane leak detection.

This article explores how infrared camera gas leak detection works, its key advantages, and a practical application case in methane leak detection and monitoring.

1. Understanding Thermal Imaging Gas Leak Detection

All objects above absolute zero emit infrared radiation, and the intensity of this radiation increases with temperature. A thermal imaging camera converts invisible infrared radiation into visible images, revealing a detailed temperature distribution of the target area.

Gas molecules absorb infrared light at specific wavelengths, and different gases have distinct absorption peaks. Based on this principle, Raythink’s infrared gas detection cameras employ high-performance custom filter detectors to capture infrared radiation differences within characteristic absorption bands. This allows invisible gases to be visualized as clear infrared thermal images, enabling precise and rapid gas leak detection.

The technology provides non-contact, long-range, and wide-area gas leak monitoring without interrupting production. It allows operators to locate leaks in real time, assess the scale, and respond effectively, thereby enhancing safety, efficiency, and accuracy in industrial inspections.

2. Why Use Gas Leak Camera for Methane Leak Detection

1) Limitations of Traditional Methane Leak Detection Methods

· Limited coverage: Conventional methods cannot effectively monitor large areas or pinpoint leaks in complex industrial environments, resulting in time-consuming and labor-intensive processes prone to oversight.

· High operational risks: Detection personnel must approach or even come into direct contact with leaking gases, exposing them to severe safety hazards such as poisoning and explosions.

· Low efficiency: Long detection cycles typically allow only periodic inspections, making real-time monitoring largely impossible and preventing timely detection of sudden leaks.

· Maintenance requirements: Some sensors are susceptible to environmental factors, necessitating periodic upkeep. Their lifespan and stability may also be compromised.

2) Advantages of Gas Detection Camera as Methane Leak Detection Equipment

Compared with conventional tools, an infrared gas detection camera offers multiple distinct advantages:

· Non-contact long-distance detection: Operators can inspect gas leaks from a safe distance, avoiding direct contact with flammable gases like methane and thereby protecting personnel safety.

· Visualized, intuitive localization: Infrared imagery enables operators to visually monitor the location, plume size, and dispersion direction of gas leaks.

· Efficient large-area scanning: The coverage of broad zones eliminates manual point-by-point checks, significantly reducing detection time and boosting operational efficiency.

· No downtime required: Inspections can proceed while equipment remains operational, eliminating the need for shutdowns or production halts and thereby minimizing production losses. This is particularly crucial for continuous manufacturing operations.

· Easy recording and traceability: Detection results can be saved in real-time as images or videos, providing robust support for subsequent maintenance, accountability tracing, and compliance verification.

3. Methane Leak Detection Application Case: Thermal Camera Gas Leak Detection at a Natural Gas Storage Facility

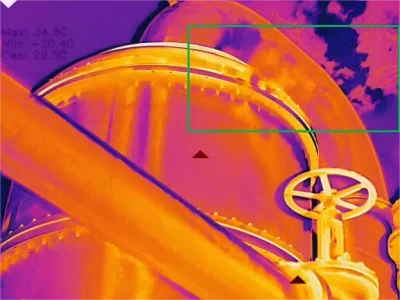

Natural gas storage facilities serve as critical hubs in energy transportation, bearing the vital responsibility of ensuring secure natural gas supply. However, due to the numerous pieces of equipment and complex sealing points within these facilities, plus natural gas’s flammable and explosive properties, any leakage—from pipelines, valves, or storage tanks—could lead to catastrophic consequences, threatening the site’s operational stability and worker safety.

Monitoring target: Natural gas (Methane) leak detection

Coverage: Full site monitoring through an integrated deployment strategy of “fixed monitoring + mobile inspection”

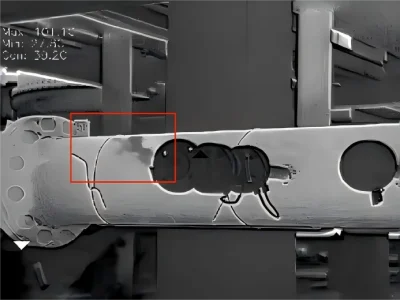

Focus areas: Pipelines, storage tanks, and other critical components

Deployment strategy:

To enhance safety awareness and risk prevention, Raythink developed a hybrid model combining fixed and mobile thermal camera gas leak detection: Fixed online gas detection cameras create an all-weather, omnidirectional, three-dimensional gas leak surveillance network; handheld infrared gas detection cameras conduct frequent inspections and quick verifications of potential leaks. The result is an intelligent defense system combining automated monitoring with agile response capabilities—one that enables early detection, rapid response, and effective handling of gas leaks, thereby enhancing the risk prevention and emergency response efficiency of gas storage facilities.

Explosion-Proof Gas Imaging PTZ Camera + OGI Handheld Camera

1) Fixed Online Monitoring:All-Weather Monitoring for Real-Time Protection

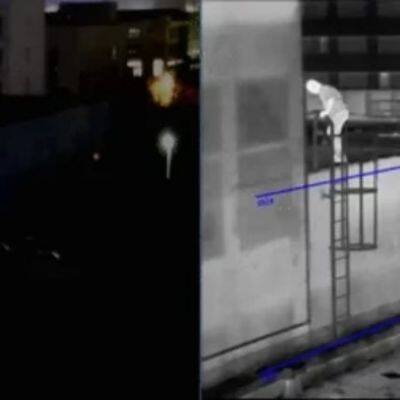

Installed in key areas of the gas storage facility, the explosion-proof gas imaging PTZ camera enables 24/7 real-time gas leak visualization. Dual-spectrum high-definition imaging (infrared and visible light) automatically patrol and scan along preset routes, continuously capturing and recording gas leak dynamics.

Monitoring footage is transmitted in real-time via network systems to the control center, allowing personnel to remotely view and analyze leak conditions. Manual pan-tilt control enables flexible angle adjustments for targeted inspections of critical areas such as pipelines and valves.

· Infrared+ visible light HD imaging: All-weather automated scanning reveals all potential leak hazards.

· Remote PTZ control: Supports manual operation to adjust monitoring angles on demand.

· Historical data retrieval: Automatically stored data enables real-time tracking and verification.

2) Mobile Handheld Inspection: Rapid Leak Detection for Precise Inspection and Verification

The OGI handheld camera is lightweight, flexible, and ready to use, ideal for routine inspection, emergency verification, and other mobile monitoring needs. It enables rapid scanning of large areas, identifying and confirming suspected gas leaks, covering blind spots missed by fixed monitoring systems.

Gas leaks invisible to the naked eye appear clearly on the thermal camera’s screen, enabling inspectors to promptly identify issues, pinpoint sources, and initiate repairs. This enhances inspection efficiency and response speed to prevent risk escalation.

· Portable and efficient: No installation required; deploy anytime to adapt flexibly to various scenarios.

· Quick leak localization: Infrared visualization enables immediate detection and localization of gas leaks.

· Efficient coverage: Rapid scanning of large areas reduces inspection time, enhancing efficiency while maintaining reliability.

4. Raythink Methane Leak Detection Equipment Recommendations

TE464G1 Explosion-Proof Gas Imaging PTZ

RG600C OGI Handheld Camera

Raythink Thermal Imaging Gas Leak Detection Advantage:

· High-performance detector: Specialized high-sensitivity infrared detectors paired with advanced gas imaging algorithms enable wide-area, non-contact gas leak monitoring for precise leak localization.

· Comprehensive product portfolio for intelligent inspections: Fixed online gas detection cameras monitor critical areas and high-risk leak points in real time, while handheld gas detection cameras target potential hazards for focused inspections and rechecks.

· Intelligent coloring: Proprietary AI gas plume coloring algorithm precisely captures and segments gas leak zones, clearly displaying plume contours and dispersion directions. Users can intuitively assess leak intensity and diffusion trends by observing colored plume size and shape, enabling timely emergency response and enhanced safety capabilities.

· Concentration inversion analysis: Raythink’s proprietary gas algorithm not only provides visual gas plume concentration but also integrates high-precision concentration inversion technology to accurately identify and quantify gas concentration values. Users learn the gas leakage level through real-time changes in the concentration bar, which allows accurate risk evaluation and corresponding response.

· Smart alarm system: Integrated smart alarm technology triggers automatic alerts even at minimal leak concentrations. This assists users in fast gas leak detection, troubleshooting, and repair, enhancing maintenance efficiency and safety response capabilities.

Visible Light Imaging vs. Infrared Thermal Imaging

5. Conclusion

Thermal camera gas leak detection has become the core solution of modern industrial methane leak detection. Its comprehensive advantages in visualization, safety, efficiency, and environmental protection make it indispensable across the entire natural gas value chain, from extraction and processing to transport and storage.

As an industry-leading thermal imaging solutions provider, Raythink delivers reliable, end-to-end methane leak detection solutions for industrial gas safety. For a customized methane leak detection equipment deployment strategy tailored to your operations, contact the Raythink team to reserve a professional, personalized consultation.

Recently Posted

-

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

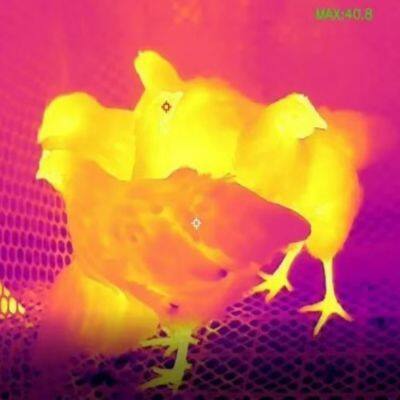

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More -

Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

January 22, 2026Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. D Read More

Read More