The Application of Thermal Cameras in Transformer Fault Detection and Preventive Maintenance

1. Application Background

As the core key equipment for power transmission and voltage conversion in the power grid, the safe and stable operation of transformers is directly related to the reliability of regional power supply. Transformers have a complex structure, including the transformer body, bushings, cooling devices, and other core components. Operating under high-voltage and heavy-load conditions for a long time, they are prone to various faults due to insulation aging, poor contact, component wear, etc. Moreover, most faults are accompanied by abnormal heating before occurrence. Real-time and accurate monitoring of the transformer’s temperature status is a key means to identify potential defects in advance and avoid fault expansion. Raythink’s infrared thermal imaging temperature measurement technology, with the core advantages of non-contact detection, real-time imaging, and accurate temperature measurement, has become an effective technical solution for transformer fault detection and preventive maintenance in the live state. Targeting different detection scenarios such as the transformer body and bushings, Raythink has developed adaptive infrared inspection products, which can quickly identify and locate various heating defects, helping operation and maintenance personnel fully grasp the equipment’s operating status, provide data support for transformer preventive maintenance, and ensure the long-term stable operation of the equipment.

2. Application Scenarios

1) Transformer Body Fault Detection

Transformers are one of the most critical equipment in the power grid, responsible for power transmission and voltage conversion. Transformer components include the body, cooling devices, voltage regulation devices, protection devices (such as gas relays, oil conservators, temperature measurement devices), and outlet bushings. Currently, infrared temperature measurement is an effective detection method for transformers in the live state. Through infrared thermal imaging technology, a large number of different types of defects can be found in the transformer body, oil conservator, bushings, coolers, and their control circuits.

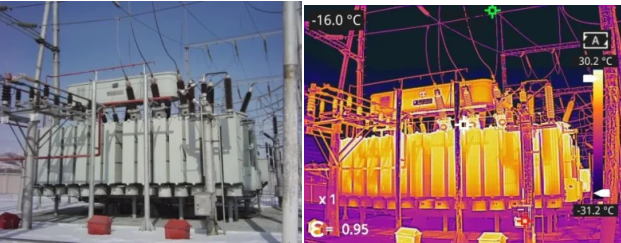

The transformer body consists of an iron core, windings, oil tank, insulating oil, etc. Due to its large volume and internal oil circulation, it is difficult to detect internal faults or defects of the transformer through infrared detection. However, heating defects such as magnetic flux leakage can be detected. Typical thermal images of heating defects are shown below.

2) Transformer Bushing Fault Detection

Transformer bushings are insulating sleeves that lead the high-voltage and low-voltage leads inside the transformer to the outside of the oil tank. They not only insulate the leads from the ground but also fix the leads and conduct load current for a long time. According to their structure, bushings can be divided into capacitive, oil-filled, and pure porcelain bushings. Capacitive bushings are composed of conductive rods, capacitor screens, insulating oil, outer porcelain sleeves, etc., and are mostly used in transformers with a voltage level of 35kV and above. Their failure rate is also relatively high. Through infrared detection methods, various defects such as oil shortage in bushings and excessive dielectric loss of main insulation can be found. Typical thermal images of heating defects are shown below.

3. Raythink Product Recommendations

Recently Posted

-

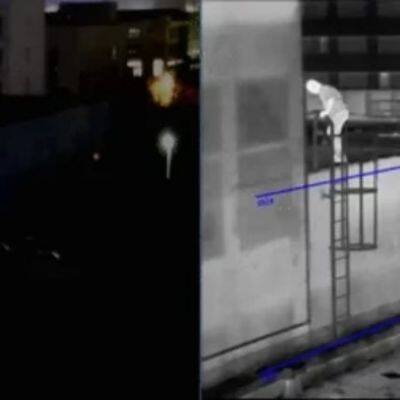

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

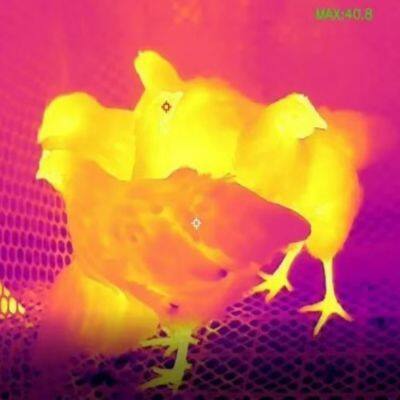

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More -

Infrared Thermal Camera for Temperature Visual Monitoring in Logistics Cold Chain Vehicles

January 22, 2026Temperature monitoring during refrigerated truck transportation is a key application of thermal cameras in cold chain logistics. D Read More

Read More