Thermal Camera Application in Gas Detection

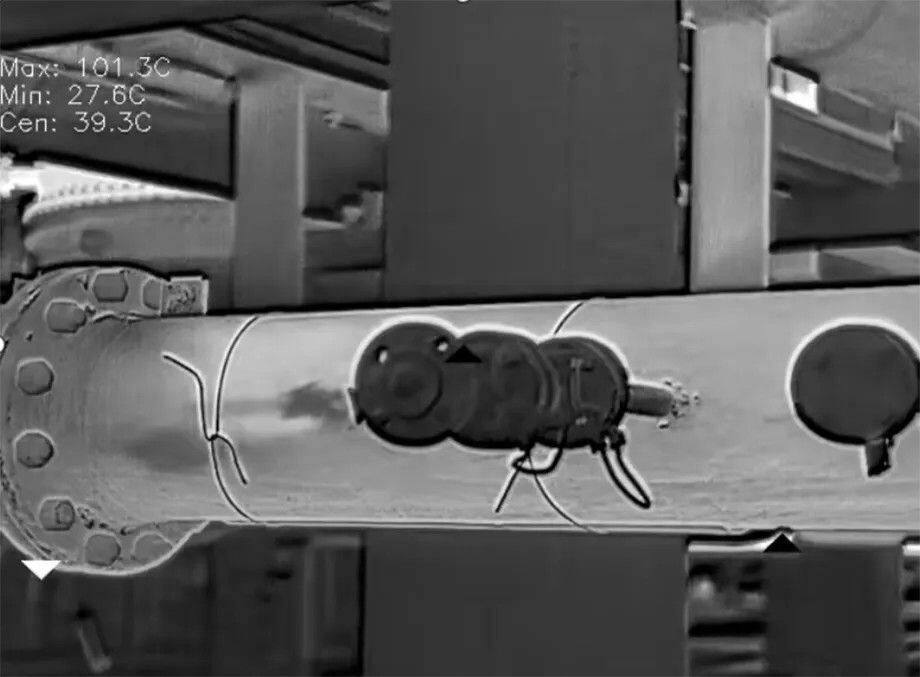

A thermal camera for gas leaks can detect a large area at a long distance and in a non-contact manner according to the ambient temperature change caused by gas leakage.

Once there is gas leakage, the temperature will be abnormal, which will be displayed as a plume of smoke on the thermal camera. Thus, the visualization of the leaking gas can be realized to help inspectors locate the leakage position in real time, judge the scale of the gas leakage, and eliminate hidden dangers on time.

2.Thermal Camera for Gas Leak Detection

2.Thermal Camera for Gas Leak Detection

Thermal cameras for gas leaks can detect the temperature change caused by gas leakage and display a panoramic image of the scanned area. Once there is gas leakage, it will be displayed as smoke on the thermal camera, which can help inspectors to see and locate the leakage quickly.

3)Long-distance and Non-contact DetectionTraditional gas leakage detection requires contact with gas, and the inspector may be exposed to potentially harmful chemicals. While, thermal camera for gas leakage can carry out non-contact

detections, which can effectively avoid the potential health threat of harmful substances to the inspectors.

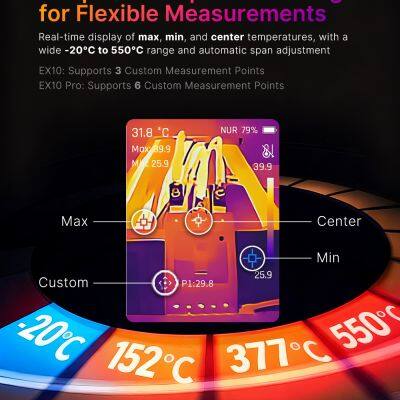

The thermal camera can quickly and accurately obtain the two-dimensional temperature distribution on the surface of equipment and materials and automatically capture the hottest point in the detection area. Meanwhile, the thermal camera supports point/line/area temperature measurement. Users can select the temperature measurement targets according to their needs, such as detecting the corrosion, fracture, thinning, blockage, and leakage of gas transmission and pipeline, fire-resistance and thermal insulation materials, and various reaction furnaces. Inspectors can visually see the problems and accurately locate them to find out the root cause of the fault reliably and accurately.

3.Thermal Camera Applications in Gas Leak DetectionAt present, the commonly used gas detectors can only detect the existence of gas leakage, but it is difficult to locate the specific leakage position. It also takes a long time to check based on the change in gas concentration.

Thermal cameras can be applied in gas leakage detection for the following reasons:

(1) Thermal cameras can vividly detect the low temperature caused by gasification in the case of natural gas leakage.

(2) The methane content in natural gas is generally 85%, and the infrared band is 7.0-8.5 μm, which a thermal camera can display.

1)Oil and Gas ExploitationThermal cameras for gas leakage can be applied in the oil and gas production industry to visualize gas leakage, locate gas leakage areas in advance, and avoid accidents such as dangerous gas emissions. It plays an important role in the prevention and maintenance plan and helps to ensure the safe production of enterprises.

2)Natural Gas Transmission and Distribution

2)Natural Gas Transmission and Distribution

Natural gas is transported to thousands of households and industrial and commercial users in cities. Due to the explosive nature of gas, gas leakage often causes disastrous consequences. Thermal cameras for gas leakage can detect tiny natural gas leaks and scan the gas pipelines to locate the leakage location, thus ensuring the life safety of users.

3)Crude Oil Refining

3)Crude Oil Refining

A typical refinery includes two types of processes: separation and conversion. The separation process splits crude oil into useful components, which are either sold directly as fuel or used as raw materials for the next process. The conversion process modifies the molecular structure to provide products with appropriate characteristics suitable for mixing with finished fuel.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The thermal camera can make an outstanding response to the light components and intermediates produced by the fuel processing plant. So, a thermal camera is ideal for monitoring the volatile gas in the process of crude oil fractionation, which is beneficial to the inspectors in improving the process flow of oil refining and assisting the enterprise in efficient production.

4)Equipment Failure Detection

4)Equipment Failure Detection

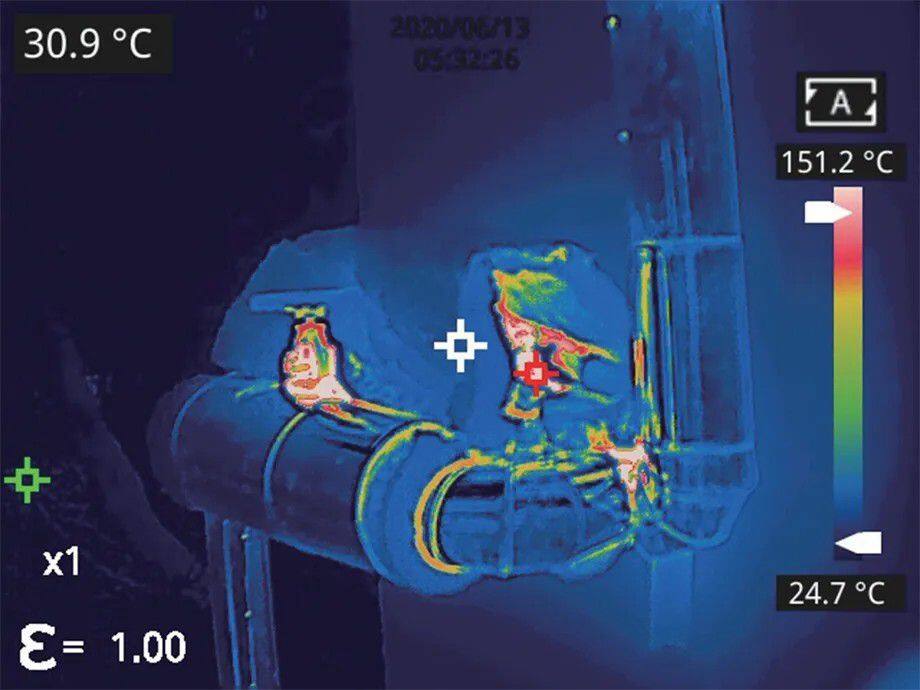

Since there are a large number of chemical reactions accompanied by a certain temperature in production, different degrees of corrosion will occur, resulting in the damage or thinning of the moisturizing layer, pipe walls, valves, heat exchangers, and cap linings.

With a thermal camera, relevant production equipment can be scanned in an all-around way, and abnormal temperature points in the detection area can be automatically captured. Therefore, the inspectors can understand the damage status of the equipment, accurately locate the damaged parts, and take preventive and maintenance measures for the equipment in time. Effectively avoid the occurrence of gas leakage and the loss of energy.

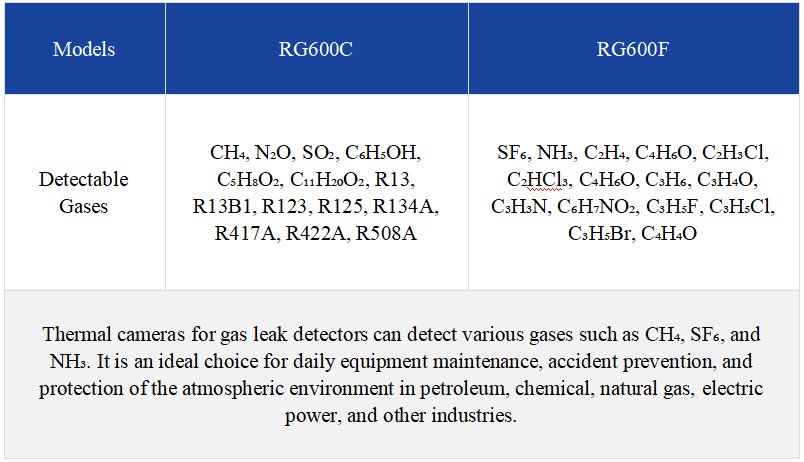

5) Environmental Protection Law EnforcementCH₄, SF₆, NH₃, and other gases can be detected by the thermal camera for gas leakage. With the thermal camera, the inspectors of the environmental protection law enforcement department can accurately identify the emission source, detect the emission of relevant gases and substances in the air of the plant, and judge whether the environmental quality in the plant meets the standards to ensure its compliance with laws and regulations.

Recommended Thermal Camera Products by Raythink

Recommended Thermal Camera Products by Raythink

Cautions for Use

· In the gas detection mode, you can set parameters of gas enhancement in the first-level menu and set gas detection gear in the second-level menu to adjust the gas detection effect. After setting the gas enhancement parameter, click any area on the screen to make the setting take effect.

· In the temperature measurement mode, set the temperature measurement gear in the secondary menu to meet different temperature targets.

· When using DDE, PIP, or fusion mode for a better dual-light image effect, you need to set the actual distance, that is, the approximate distance between the thermal camera and the object. If the preset parameters cannot meet the requirements, you can also manually perform fusion registration in the settings.

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More