How to Use a Thermal Imaging Camera for HVAC and Building Inspections?

1. Introduction

In the inspection and maintenance of building and HVAC systems, temperature serves as one of the critical diagnostic indicators. Traditional inspection methods often rely on empirical judgement or partial dismantling for examination, which are not only inefficient and highly destructive but also struggle to identify potential hazards in a timely manner. With the deepening application of infrared thermal imaging technology in the building and HVAC sectors, inspection methods are shifting from ‘spot checks’ to ‘visual diagnostics’, delivering more efficient and reliable technical means for the operation and maintenance management of building and HVAC systems.

Thermal imaging cameras for HVAC and building inspections capture infrared radiation emitted by object surfaces, presenting temperature distribution variations in a non-contact, real-time, and visual manner. This enables inspectors to swiftly identify anomalous areas, facilitating efficient assessments of building structures and HVAC system operational status. Whether for air conditioning equipment fault detection, uneven underfloor heating analysis, thermal pipe defect investigation, external wall cavity identification, roof leakage detection, or building airtightness assessment, infrared thermal imaging cameras can pinpoint problem sources without structural damage, significantly enhancing inspection efficiency and maintenance quality.

This article provides a systematic analysis covering typical application scenarios, inspection advantages, and product selection criteria. It aims to offer users a comprehensive understanding of infrared thermal imaging applications within building and HVAC diagnostics, outlining practical implementation pathways. This serves as a technical reference guide for subsequent inspection, maintenance, and energy-saving retrofitting initiatives.

2. Applications of Infrared Thermal Imaging Cameras in Building and HVAC Systems

1) Air Conditioning Fault Detection

In HVAC system maintenance, malfunctions in central air conditioning equipment are a common issue. Traditional diagnostic methods often require shutdowns, dismantling equipment, and meticulously checking each component—a process that is not only time-consuming and labour-intensive but may also cause secondary damage to the equipment. Infrared thermal imaging cameras for HVAC and building offer a more efficient and safer diagnostic approach—enabling comprehensive equipment assessment while the air conditioning system remains operational. By imaging temperature distributions across surfaces such as condensers, compressors, and evaporators, anomalies like poor heat dissipation, insufficient lubrication, or frost blockages can be swiftly pinpointed. Identifying fault sources without disassembly significantly enhances troubleshooting efficiency.

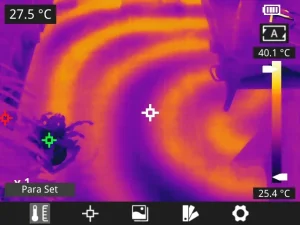

2) Underfloor Heating Fault Detection

Underfloor heating systems rely on hot water circulating through pipes beneath the flooring to transfer heat to the surface and radiate warmth into the room. Blockages or poor circulation in these pipes result in uneven surface temperature distribution, diminishing comfort. Traditional troubleshooting often requires destructive methods to locate issues, proving costly and compromising aesthetic integrity. Infrared thermal imaging, however, can clearly display the routing of underfloor heating pipes and heat distribution across different zones by imaging the surface temperature of the floor. This pinpoints the exact locations of leaks, blockages, or heat loss. Furthermore, infrared imaging can be used to determine whether manifold output is balanced; when abnormal temperatures are detected in a particular circuit, the faulty group can be swiftly identified. This non-destructive testing method significantly enhances troubleshooting efficiency and avoids unnecessary demolition work.

3) Thermal Pipeline Defect Detection

As the “arteries” of heating systems, thermal pipelines are prone to safety hazards such as heat leakage or even rupture due to ageing, corrosion, or wear during prolonged operation. Traditional inspections often rely on acoustic monitoring or pressure testing, which are inefficient and struggle to pinpoint issues accurately. This frequently necessitates extensive excavation or system shutdowns to confirm fault locations, incurring high labour and repair costs. Infrared thermal imaging cameras detect anomalous temperature distributions on pipe exteriors and valve connections, enabling rapid identification of leaks, insulation damage, or blockages without service interruption or structural damage. This achieves non-destructive testing. Paired with specialised analysis software, they generate temperature reports providing objective reference data for maintenance personnel. This optimises inspection records and helps maintain efficient, safe operation of heating networks.

4) External Wall Defect Detection

Hollow voids within external cladding or insulation layers are prevalent construction issues, compromising aesthetic quality while posing safety hazards through potential plaster detachment and pedestrian injury. As such defects often remain concealed within structures, visual inspection proves inadequate. Traditional manual tapping methods are inefficient and prone to missed defects or subjective inconsistencies. Infrared thermal imaging cameras perform non-destructive testing by exploiting thermal conductivity differences between materials. When voids or cavities exist within the wall structure, heat transfer is impeded due to air’s significantly lower thermal conductivity compared to building materials like tiles or concrete. This creates abnormal temperature zones on the external wall surface. Under ample sunlight, hollow areas heat up rapidly, appearing as ‘hot spots’ on thermal images. Conversely, in shaded or colder conditions, these regions cool more slowly, manifesting as ‘cold spots’. Compared to traditional tapping methods, infrared inspection enables rapid, long-range scanning of entire facades without scaffolding. Results are recordable and traceable, clearly delineating damage extent and severity, significantly enhancing inspection efficiency and safety.

5) Roof Water Seepage Detection

Water ingress at building roofs, window-wall junctions, and basement ceiling slabs constitutes a common quality defect in construction projects. Traditional troubleshooting methods are not only time-consuming and labour-intensive but also prone to causing unnecessary damage. When leaks occur, the thermal mass of damp areas differs from that of dry areas. During environmental temperature fluctuations, these zones heat up or cool down at different rates—though their surface colours may appear identical to the naked eye, infrared thermal imaging reveals distinct temperature contrasts. By analysing these thermal images, inspection personnel can swiftly pinpoint leakage locations and potential pathways. This eliminates the need for indiscriminate chiselling, providing reliable evidence for subsequent repair plans. This non-destructive testing method significantly enhances inspection efficiency while effectively reducing maintenance costs.

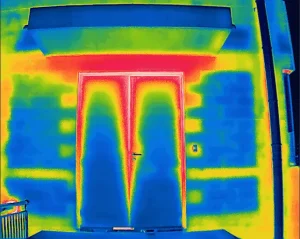

6) Air Tightness Testing

Inadequate airtightness in buildings leads to frequent exchange of warm and cold air, resulting in significant energy loss within the interior. Consequently, airtightness inspection constitutes a routine procedure in energy consumption assessments for both domestic and public buildings. During practical testing, technicians typically employ a blower door in conjunction with an infrared thermal imager. By applying positive or negative pressure within the building structure via the blower door, a pressure differential is created between the interior and exterior. Where air leakage occurs, the rapid movement of air alters local temperatures. Infrared thermal imaging cameras detect these minute temperature variations, revealing distinct cold spots or thermal bridges. This enables rapid leak detection, providing clear guidance for subsequent sealing and repairs, thereby significantly enhancing the efficiency of energy-saving retrofits.

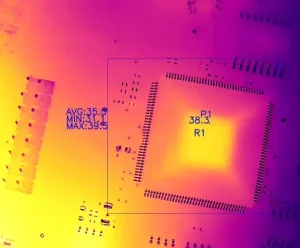

7) Electrical Equipment Operational Monitoring

The secure and stable operation of electrical systems underpins the reliable functioning of HVAC equipment, making routine inspections of electrical circuits and components paramount. Leveraging its high-sensitivity temperature detection capabilities, the thermal imaging camera swiftly identifies temperature anomalies caused by ageing wiring, poor contacts, three-phase imbalance, or overload conditions while equipment remains energised, precisely pinpointing hotspots. When paired with specialised temperature analysis software, they can assess temperature rise trends in electrical components, enabling visualised management and trend-based early warnings. This empowers maintenance personnel to formulate proactive maintenance plans, achieving ‘early detection, early identification, and early resolution’ to comprehensively foster a secure and reliable electrical environment.

3. Advantages of Infrared Thermal Imaging Inspection

Compared to traditional inspection methods, infrared thermal imaging offers the following advantages:

1) Non-destructive testing, safe and reliable

Infrared thermal imaging acquires temperature data non-contact, enabling inspection without dismantling equipment, interrupting operations, or damaging structures. It can remotely scan elevated surfaces or live equipment without requiring scaffolding or contact with hazardous areas, ensuring inspection safety.

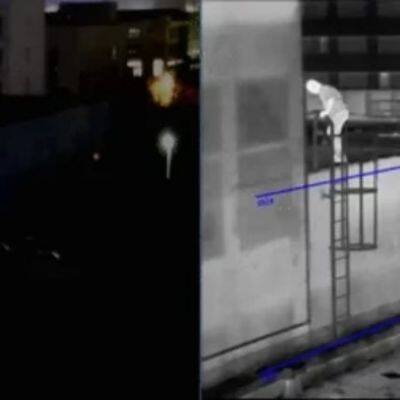

2) Visualised temperature distribution for efficient inspection

Thermal images visually represent temperature distributions invisible to the naked eye, making anomalies immediately apparent. Its rapid scanning capability enables swift coverage of extensive equipment or building structures, facilitating efficient ‘point-to-surface’ screening and significantly enhancing inspection productivity.

3) Multi-purpose device, flexible adaptation

The lightweight, portable handheld unit is ready for immediate use. It serves diverse applications including air conditioning, HVAC, building quality, and energy efficiency inspections, covering scenarios from project acceptance to maintenance follow-ups. This achieves ‘one device for multiple problem detections’.

4) Intelligent analysis, traceable documentation

Paired with professional software, it generates temperature reports and temperature curves, supporting historical comparisons, trend monitoring, and data archiving. This facilitates the establishment of inspection and maintenance records, upgrading from ‘problem detection’ to ‘problem management’.

4. Raythink Product Recommendations

5. Conclusion

Infrared thermal imaging technology is accelerating its integration into the building and HVAC inspection sectors, emerging as a vital tool for enhancing system operational reliability and energy efficiency management. From energy consumption assessment to hazard detection, and from equipment maintenance to energy-saving retrofits, infrared thermal imagers deliver more efficient, intuitive, and intelligent inspection methods for building and HVAC operations. This is achieved through their non-contact temperature measurement, real-time response capabilities, and temperature visualisation advantages.

Raythink remains committed to empowering users to achieve secure, controllable, energy-efficient, and intelligent operations through its pioneering infrared sensing technology. Should you seek to further enhance the operational efficiency of your building or HVAC systems, please contact Raythink. Our specialist team stands ready to deliver comprehensive infrared thermal imaging solutions and technical support.

Recently Posted

-

What Is The Best Thermal Camera For Electronics Repair and Rework?

February 2, 2026Electronic products face various circuit faults and hidden defects during development, manufacturing, and maintenance. Technicians Read More

Read More -

Outdoor Commercial Security Cameras: What You Need to Know

January 28, 2026In today's complex security landscape, outdoor areas of commercial properties face challenges such as theft, vandalism, survei Read More

Read More -

Four Core Scenarios: Infrared Thermal Camera Safeguards New Energy Underground Parking Facilities

January 27, 2026With the surge in the number of new energy vehicles, the fire safety risks of underground parking facilities have become increasin Read More

Read More -

Non-Contact Temperature Measurement in Biological Research via Infrared Technology

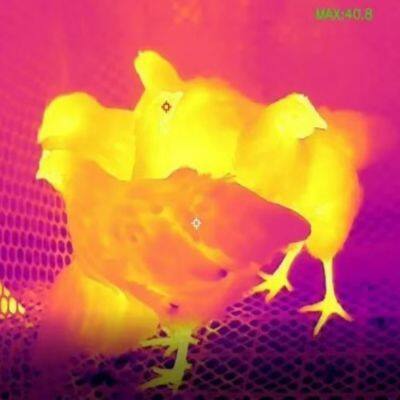

January 26, 20261. Background IntroductionIn biological mechanism research such as animal metabolic behavior analysis, body temperature serves as Read More

Read More