How Gas Leak Detection Cameras Transform Industrial Safety and Environmental Protection

With the acceleration of industrialization, various gases are widely used in industries such as petroleum, chemical, and power. However, gas leaks can not only cause severe environmental pollution but also pose health risks and even trigger fires or explosions. Therefore, detecting gas leaks is of critical importance. Traditional gas detection methods often suffer from low efficiency, limited coverage, and difficulty in quickly pinpointing leak sources under complex conditions. In high-risk environments, there is an urgent need for an efficient and safe detection solution.

A gas leak detection camera, or infrared gas imaging device, can convert invisible gas leaks into intuitive thermal images, enabling long-distance, non-contact, real-time monitoring. With advantages such as high sensitivity and visualization, infrared gas imaging cameras are becoming essential tools for detecting gas leaks across various industries.

This article will provide a comprehensive overview of the working principle, main advantages, application scenarios, and precautions of infrared thermal imaging in gas leak detection. It will also recommend suitable products, offering guidance for companies in selecting an efficient and reliable gas leak detection camera solution.

1.Principles of Infrared Thermal Imaging for Gas Leak DetectionGas leak detection using infrared thermal imaging is achieved by combining the principles of infrared imaging with the infrared absorption spectral characteristics of gas molecules.

1) Infrared Imaging PrincipleAny object with a temperature above absolute zero (-273°C) has molecules and atoms in random motion, continuously emitting infrared radiation. The intensity of this radiation varies at different points on the object due to temperature differences. Infrared imaging technology converts the infrared radiation emitted by the target into electrical signals via an infrared imaging system, producing an image on a display that is visible to the human eye and can be processed by a computer. A gas leak detection camera uses this principle to visualize gas emissions that are otherwise invisible.

2) Infrared Absorption Spectroscopy PrincipleMolecules are composed of atoms connected by chemical bonds, with continuous motion including electronic transitions, atomic vibrations, and molecular rotations. When molecules absorb external energy, their energy levels transition from the ground state to excited states. When exposed to infrared light of varying frequencies, molecules absorb specific frequencies, causing changes in the molecular dipole moment and resulting in decreased transmission intensity at those frequencies. This produces the infrared absorption spectrum unique to each substance. Different gases have distinct absorption spectra due to differences in molecular structure. For many gases, ideal detection occurs within the 2.5–7.52 μm and 7.4–16.67 μm wavelength bands, where absorption peaks are concentrated and atmospheric attenuation is minimal.

3) Gas Detection Principle Using Infrared Thermal ImagingTaking SF₆ gas as an example, it exhibits infrared absorption within the 10.4–10.9 μm wavelength range, with the strongest absorption at 10.6 μm. Infrared radiation passing through SF₆ in this band is partially absorbed before reaching the infrared imaging system, creating an intensity difference between the absorbed radiation and background radiation. This difference forms a visible thermal image of the gas cloud, allowing the gas leak detection camera to identify and locate leaks accurately.

2.Key Advantages of Thermal Imaging for Gas Leak Detection1) Non-Contact Detection – Safer OperationInfrared thermal imaging provides a completely non-contact method of detection, avoiding direct contact with equipment or gas. This is especially critical when monitoring toxic, hazardous, or high-temperature gases. Non-contact detection significantly reduces operational risks. Additionally, because the detection process does not physically touch the equipment, it prevents potential damage to the target system, making it ideal for safe inspections in complex environments. A gas leak detection camera offers this essential safety advantage.

2) Remote Monitoring – Ideal for Hazardous EnvironmentsInfrared thermal cameras support long-distance observation, covering wider areas that may be difficult or dangerous for personnel to access, such as high platforms, deep wells, or narrow spaces. Inspectors can detect leaks quickly from a safe distance, minimizing exposure to risk.

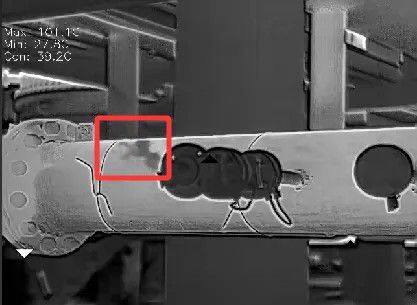

3) Large-Area Rapid Scanning – Efficient Leak Source IdentificationThermal imaging cameras enable real-time, large-area scanning. Compared to traditional manual sniffing or point sensors, efficiency is greatly improved. Leak points appear clearly on thermal images, allowing inspectors to conduct rapid, wide-area inspections and quickly pinpoint abnormal zones, shortening the investigation cycle.

4) Visual Imaging – Making Invisible Gases “VisibleInfrared imaging can display leaking gases in the form of visible “gas clouds,” showing the location and extent of leaks at a glance. Detection results no longer rely solely on experience but are presented visually, enabling precise localization and reducing unnecessary repairs.

5) Multi-Gas Detection – Flexible and VersatileInfrared gas imaging cameras can detect multiple gases simultaneously, adapting to diverse application scenarios. This versatility allows a single gas leak detection camera to achieve efficient monitoring while improving equipment utilization and return on investment.

6) Environmentally Friendly – Safe and SustainableThe detection process does not require chemical reagents and produces no secondary pollution, posing no health risks to operators or harm to the environment. Rapid detection and reduction of gas leaks also help lower emissions and environmental impact, making thermal imaging an eco-friendly detection solution.

3.Application Scenarios of Infrared Thermal Imaging for Gas Leak Detection1) Oil & Petrochemical – VOCs Leak Detection in Storage TanksTraditional manual inspections have inherent limitations, which often leads to overlooking potential safety hazards. A gas leak detection camera with long-distance, non-contact detection capability can quickly scan high storage tanks—up to several meters tall—focusing on vulnerable areas such as breathing valves and foam generators. Gas leaks are visualized as intuitive thermal images, allowing maintenance personnel to identify leak points accurately without climbing to elevated locations. This enables timely repairs, preventing fire or explosion hazards while reducing raw material losses.

2) Natural Gas Transportation – CH₄ Pipeline Leak DetectionNatural gas is the third-largest energy source after petroleum and coal, and pipeline safety is critical. Being colorless and odorless, natural gas leaks are invisible to the naked eye, yet can cause serious accidents. Pipelines have numerous sealing points, and leaks often occur as tiny gas flows, which traditional methods struggle to detect. A gas leak detection camera with high-sensitivity detectors can rapidly scan from a safe distance, accurately capturing leakage traces. This not only ensures pipeline safety but also helps reduce greenhouse gas emissions.

3) Power Industry – SF₆ Gas Leak Detection in Electrical Equipment SF₆gas is widely used as an insulating medium in high-voltage electrical equipment, including transformers, circuit breakers, and switchgear. Leaks can negatively impact power grid operation and damage equipment. While conventional leak detectors can perform qualitative and quantitative measurements, they often fail to quickly and visually locate leaks in complex environments. In contrast, a gas leak detection camera allows remote, real-time observation without shutting down equipment. Leaks and their extent are clearly visible, significantly reducing detection complexity, improving accuracy, and enabling maintenance personnel to pinpoint and fix issues promptly, effectively preventing equipment failures and power outages.

4) Environmental Monitoring – Refrigerant (Freon) Leak DetectionFreon leaks are common in refrigeration systems, exacerbating the greenhouse effect, causing long-term environmental harm, and posing serious safety risks. Freon is flammable, and leaks near open flames can produce toxic gases, directly threatening health and safety. Traditional detection methods—visual inspection of sight glasses, irregular patrols for oil stains, or handheld refrigerant leak detectors—are often inefficient and struggle to accurately locate leaks, leading to missed detections or false positives. A gas leak detection camera can be efficiently applied in refrigeration rooms, as well as during Freon storage and transport. Real-time imaging clearly shows leak locations and scale, allowing personnel to respond immediately, improving inspection efficiency, reducing refrigerant waste, and helping companies comply with environmental regulations while minimizing carbon emissions and safety hazards.

4. Raythink Product Recommendations

To ensure the accuracy and reliability of infrared gas imaging detection, the following key factors should be considered during use to optimize detection results and improve efficiency:

1) Proper Equipment SelectionMatching the gas’s spectral absorption peaks with the wavelength range covered by the thermal imaging system is essential for effective gas leak detection. Therefore, selecting the right equipment is crucial.

2) Avoid Light InterferenceSunlight or artificial light sources contain significant infrared radiation, which can mask gas leak signals if directly shining on the optical lens, reducing the temperature contrast in the image. Additionally, smooth surfaces may reflect light, and even backlighting can affect imaging quality. Detection should therefore be performed away from strong sunlight or bright artificial lighting.

3) Pay Attention to Background Temperature DifferencesBackground temperature differences are a critical factor affecting infrared image quality. In practice, adjusting the background temperature can enhance the temperature contrast in the image, making leaking gas more clearly visible.

4) Control Wind ConditionsWind speed affects the dispersion of leaking gas. High wind speeds can disperse gas before a clear temperature contrast appears in the image, while completely still air may prevent the formation of a dynamic “cloud-like” image, making interpretation difficult. Detection should be conducted under suitable wind conditions to ensure clear and accurate imaging.

5) Combine with Other Detection TechnologiesAlthough infrared gas imaging offers advantages such as wide coverage, long-range detection, and fast response, its effectiveness can be limited by factors like the radiation contrast between the target and background, and it cannot identify the type of leaking gas. In practice, combining infrared imaging with other detection methods creates a multi-dimensional monitoring system, enhancing comprehensive gas leak monitoring and early warning capabilities.

6.SummaryWith increasing safety and environmental requirements in industrial production, timely detection of gas leaks has become crucial. Infrared gas imaging cameras offer a high-efficiency, safe, and reliable solution, thanks to their non-contact, long-range, and visual detection capabilities. By applying infrared thermal imaging technology, companies can quickly pinpoint leak sources, reduce the risk of accidents, and minimize environmental pollution, supporting sustainable development. For professional guidance on equipment selection and tailored solutions, contact the Raythink team to build an efficient and reliable gas leak monitoring system.

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More