Application of Thermal Cameras – Detection of Compressor Refrigeration

The compressor, generally composed of the housing, motor, cylinder, piston, control device (starter and thermal protector), and cooling system, is the heart of the refrigeration system.

Refrigerant leakage can prolong the compressor’s operating time and lead to issues such as incomplete or missing frosting on the evaporator, product defects, energy loss, and poor refrigeration performance.

Abnormal temperatures of the compressor housing can negatively affect its service life; temperature abnormalities in the motor housing or bearings may cause the motor—and the entire refrigeration system—to shut down; abnormal temperatures in the cylinder or coolant outlet can paralyze refrigeration; and temperature issues in the control device can reduce system stability and shorten component lifespan.

A thermal camera can accurately locate refrigerant leaks, helping to prevent continuous leakage and reduce energy loss. In addition, it can monitor the housing, motor, cylinder, coolant outlet, and control device of the compressor system to track its operating status and improve efficiency.

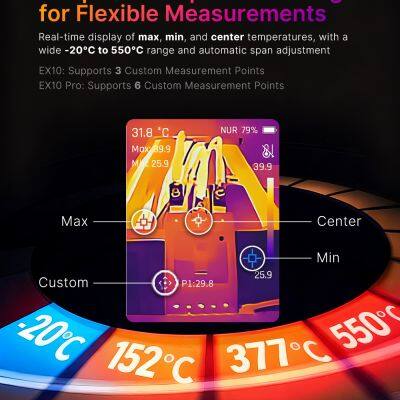

Non-contact temperature measurement is achieved.

The system automatically captures the hottest spot on the screen or within a specified area, making problems immediately visible and enabling accurate fault localization. It helps reliably and precisely identify the root causes of faults.

Alarm threshold settings are supported.

When the temperature reaches the preset threshold, an alarm is triggered to promptly notify staff to take appropriate action.

Temperature information is visualized.

Temperature readings are displayed on the screen, allowing users to view the temperature of any selected area. This feature supports large-area monitoring needs.

SDK for secondary development is available.

Alarm messages can be transmitted via IO port, serial port, or other interfaces, supporting flexible device integration and secondary development.

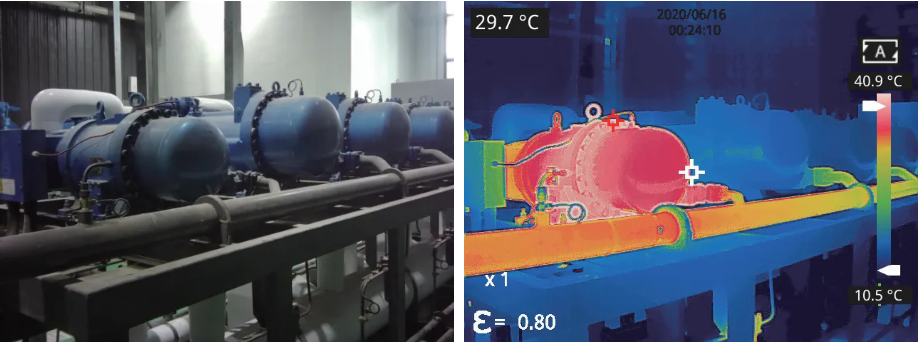

In the process of design, welding, and production, minor refrigerant leakage occurs at the refrigerant pressure vessel and steel pipe due to poor welding or steel pipe quality, which leads to rapid consumption of refrigerant.

The thermal camera can be used for temperature measurement of the refrigerant vessel and steel pipe, identify the points with an abnormal temperature visibly, accurately locate the positions of refrigerant leakage, and prompt the staff to take remedies in time to prevent energy loss and stabilize refrigeration of the compressor.

Temperature Measurement of the Compressor HousingAbnormal operations of the cooling system or an excessively heavy load will give rise to temperature abnormalities of the compressor housing, which will have an adverse effect on the service life of the compressor.

Detection of Refrigerant Leakage

The thermal camera can be used to conduct a large-area and omnidirectional scan of the compressor housing, acquire the overall temperature data of the compressor housing and automatically capture the hottest spot on the screen or area to make problems directly visible and allow accurate problem locating. It helps ascertain the root causes of faults in a reliable and precise manner.

Temperature Measurement of the Compressor Housing

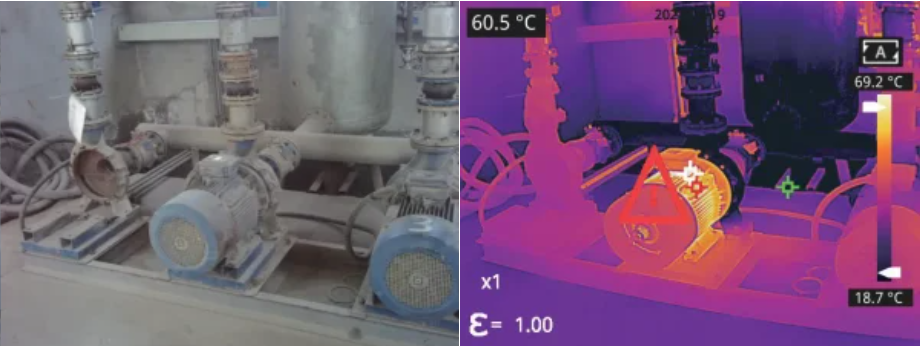

Temperature Measurement of the Motor

During motor operation, excessively high or uneven temperatures on the motor housing may result from poor or uneven heat dissipation, aging of internal coils, insufficient load capacity, or poor power supply quality. Abnormal temperatures in the motor bearing are typically caused by inadequate lubrication or shaft misalignment.

A thermal camera enables non-contact temperature measurement of the motor without interrupting device operation. It supports alarm threshold settings—when the temperature exceeds the preset range, an alarm is triggered to alert staff, allowing timely intervention and preventing shutdown of the motor and the entire refrigeration system due to thermal abnormalities.

Temperature Measurement of the Motor

Temperature Measurement of the Motor

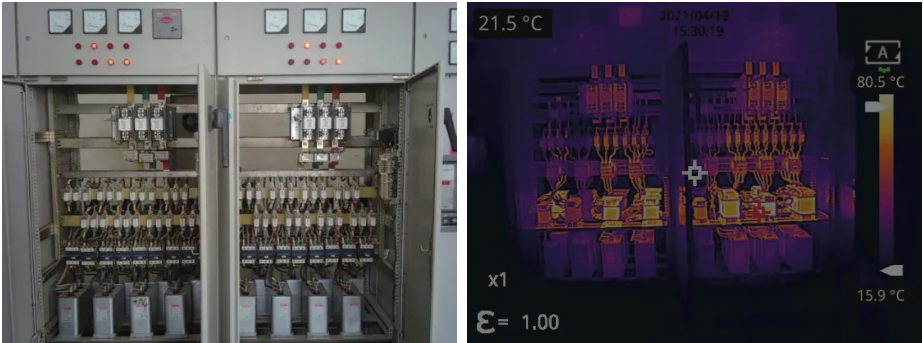

Most faults in power devices are accompanied by abnormal heating, which directly affects system stability and reduces the service life of components. A thermal camera can be used to monitor the real-time operating status of electrical devices. The measured temperature can be compared with historical data or with the temperature of similar devices in the same environment to determine whether there is a temperature rise.

The system can automatically detect and capture the hottest spot on the screen or in a specified area, identify potential fault points in time, and alert staff for preventive maintenance. This helps prevent electrical failures and fire hazards caused by thermal malfunctions in power devices.

Temperature Measurement of the Motor

Temperature Measurement of the Motor

Auto focus:more convenient field application

PoE power supply:simplified cabling

Comprehensive software functions:linkage with external alarm devices

SDK for multiple platforms:supporting secondary development

High-Resolution Imaging – 384×288 uncooled detector delivers clear thermal visuals for accurate analysis.

Real-Time Monitoring – 50Hz frame rate captures rapid temperature changes instantly.

Wide Temperature Range – Measures from -20°C to +650°C with optional lenses and compensation algorithm.

Flexible Integration – Supports Modbus, Onvif, and comes with SDK for easy system integration.

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More