Raythink Launches Ultra-high Temperature Thermal Camera, Breaking Through 2000°C Industrial Barrier

YANTAI, China, June 26, 2025/PRNewswire/– Raythink Technology Co., Ltd. ("Raythink"), an innovator in the thermal imaging industry, has launched its latest ultra-high temperature infrared thermal camera, TN460U. With an ultra-wide temperature measurement range of 0~2000°C, non-contact high resolution imaging, and strong environmental adaptability, TN460U targets the monitoring challenges of extreme-temperature scenarios in metallurgy, die-casting, and coal chemical industries.

Technological Breakthrough: Solving the Ultra-High Temperature Imaging Challenge

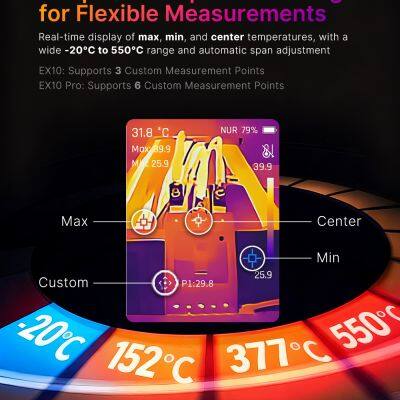

TN460U ultra-high temperature thermal camera adopts a new-generation 12μm uncooled infrared FPA detector with 640×512 high resolution. Paired with Raythink's self-developed infrared image algorithms, it delivers fine-grained real-time thermal images even in environments with strong thermal radiation interference. The core innovation lies in its stable and accurate measurement of temperatures up to 2000°C, along with synchronous 25Hz output of temperature and image data, addressing the data gap issues commonly seen above 1500°C in conventional systems.

Modular Cooling Design for Harsh Industrial Environments

Dual-channel active cooling: Optional air-cooled or water-cooled shell ensures stable operation in ambient temperatures up to 220°C; lightweight structure: Compact body (50×50×90mm) enables easy integration into constrained equipment spaces; multiple lens options: Three optional lenses with different FOV support both long-distance wide-area monitoring and close-range micro-area temperature measurement.

Scenario-Based Applications: Driving Industrial Intelligence

In metallurgy, the TN460U thermal camera captures real-time temperature distribution of molten steel, aiding in alloy composition optimization. In automotive die-casting, its millisecond-level thermal monitoring capability enables early warning of mold overheating. In coal chemical gasifiers, it enables early coking warnings through continuous temperature trend analysis. A technical manager from a glass manufacturer noted: "Fluctuations in droplet forming temperature gradients once caused a 23% deviation in light transmittance. With TN460U's real-time temperature curve analysis, our response speed to process adjustments improved fourfold."

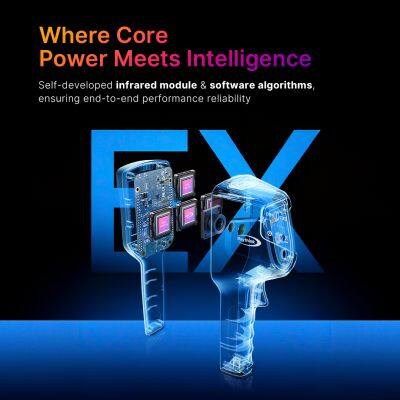

Empowering the Brand: Raythink's Technological Depth

As a leading brand in intelligent photoelectric sensing, Raythink has established a comprehensive technology portfolio in infrared temperature measurement. The launch of TN460U fills a gap in the ultra-high temperature segment and complements its existing mid- and low-temperature product lines.

According to third-party research, the global industrial temperature measurement market will exceed USD 8.5 billion by 2025, with the ultra-high temperature segment showing rapid annual growth. TN460U delivers a high-precision solution for use cases such as molten material monitoring and special materials sintering. Industry analysts comment: "Under the carbon peaking and carbon neutrality strategy, such devices will play an increasingly important role in energy efficiency optimization, particularly in high-consumption industries like metallurgy and glass."

Recently Posted

-

A New Paradigm of Infrared Thermal Cameras for Intelligent Monitoring and Early Fire Prevention Warn

December 30, 2025As “the kidney of the Earth”, wetlands serve as crucial stopovers for migratory birds, habitats for resident birds, and core carri Read More

Read More -

Which Security Camera Is Best For Outdoors?

December 29, 20251. The Importance of Outdoor SurveillanceIn today’s increasingly complex public security landscape, outdoor surveillance has becom Read More

Read More -

Explosion Proof Security Cameras

December 25, 20251. What Is an Explosion-Proof Security Camera?An explosion-proof security camera is surveillance equipment designed to operate saf Read More

Read More -

Four Raythink’s Products Win International Design Awards

December 23, 2025Recently, the annual final evaluation of an internationally renowned industry award focused on industrial design and manufacturing Read More

Read More